- Nuevo

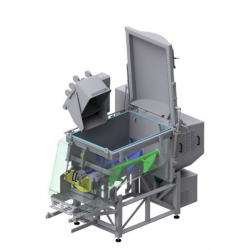

Conical mixer / vertical cone mixer and powder blender (AM)

Ideal mixing quality for dry, moist and viscous materials at variable filling levels

Descripción

The spiral mixing blade of the conical mixer initiates a three-dimensional flow of the mixing goods; creating a helical upward movement on the periphery and downward flow in the centre. This blender guarantees very good mixing results and complete discharge. It can be used as powder blender for dry powder, wet suspensions as well as liquids, paste and dough. The vertical mixer can be designed for compliance with FDA and 3-A Sanitary Standards to be used as a sterile mixer and reactor which also meets EHEDG requirements.

Further characteristics of the powder blender and conical mixer

- If the mixing process requires deagglomeration, high speed cutting rotors can be installed.

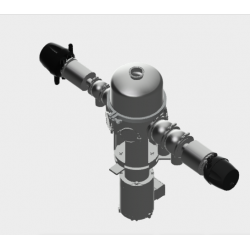

- The mixing device is driven from the top, using only a single top bearing.

- The conical mixer meets all industry standards for surface finish, including sanitary and pharmaceutical requirements.

- Jacketed and vacuum rated versions are an ideal vacuum dryer or reactor.

User benefits

✓ This precision mixer is universally applicable.

✓ Provides ideal mixing qualities in a very short mixing time.

✓ The filling levels can vary from approx. 5% to 100%.

✓ Free-flowing goods discharge up to 99.98% and better.

✓ Mixing tool driven and supported only from above. Everything is fully welded and polished without gaps.

✓ The inspection door is especially hygienic - manufactured according to the Clever-Cut® process with OmgaSeal® and seals permanently free of dead space. On request also vacuum-tight or against overpressure.

Piloting

amixon® places special importance on the pilot phase in the test centre. Your mixing processes are simulated here. This way, we support you in your product development phase.

amixon® has a main test center in Paderborn (Germany).

Further test centers are situated in Japan, Thailand, India and the USA.

- Bigger mixers up to 50 m³ are available on demand! Usually the vessel dimensions are relatively cubic. If desired, amixon® can modify the proportions: “low profile” if the height is limited or “slim profile” if the available ground area is limited.

- As a welding specialist, amixon® is qualified by European, Japanese and American authorities with regard to different materials. The materials in contact with the mixing goods are either mild steel S355J2Ge, Hardox, austenitic stainless steels 1.4301, 1.4541, 1.4571, 1.4404, 1.4539, 1.4529, Duplex stainless steels 1.4462, 1.4162, 1.4363 and Alloy 59-2.4605, Hastelloy C22 and nickel.

- The mixers meet the highest hygienic requirements and comply with the EHEDG guidelines for dry and wet cleaning regime. They also meet the FDA hygiene guidelines and the design requirements of 3-A Sanitary Standards.

184 otros productos en la misma categoría:

- Nuevo

Continuous drum coating machine for adding spices and flavors AD

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT