- Nuevo

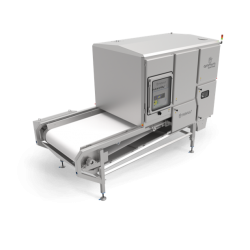

Reversible flow filter TURBO

The reversible flow filter TURBO serves to clean the cooling lubricants of machining processes (e.g. milling, turning, drilling).

Descripción

Areas of application

The reversible flow filter TURBO serves to clean the cooling lubricants of machining processes (e.g. milling, turning, drilling). The modular system allows the filter to be used both decentrally at individual machines as well as installed in central plants. The filter works according to the backflush principle and does not require any filter consumables. The scraper belt conveyor which serves as sediment basin, discharge conveyor and liquid buffer, is especially suited for handling the concentrated backflushing liquid. If necessary, the plant can be expanded with a bath care in bypass flow (e.g. belt filter or centrifuge) in order to prevent accumulation of not sedimented fine particles.

Properties

Modular system

Can be used with a wide range of plants

Good expandability

Simple, service-friendly design

No filter aids are necessary

Function

Filtering

Contaminated liquid flows in tangentially through the inlet into the outer part of the filter body. Due to centrifugal force, part of the solids are separated which then settle at the outer housing wall. After flowing through the filter element, which holds back further particles, the liquid reaches the clean area and then the outlet. On the filter element, a filter cake is formed which even separates very small particles. The liquid pressure compresses the air in the reversible flow buffer which then fills up with clean liquid.

Regeneration

The growing filter cake causes the volumetric flow through the filter element to decrease. The regeneration phase begins when a set differential pressure between the contaminated and clean liquid is reached: The drain valve opens while at the same time the clean liquid outlet closes. The air in the reverse flow buffer releases and presses the liquid via a rotating backflushing nozzle from the inside through the filter element. As a result, the filter cake dissolves and then moves through the drain valve to the processing plant (sedimentation basin or belt drive).

73 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT