- Nuevo

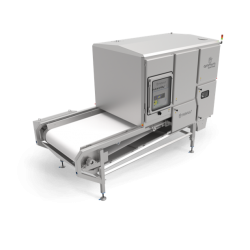

Rotary pressure filter RPF

PROCESS ENGINEERING VERSATILITY FOR FILTRATION

Descripción

Highly efficient pressure filtration and cake washing

The BHS rotary pressure filter (type RPF) is a continuously operating filter for pressure filtration. It facilitates gas-tight cake handling in a series of separate process steps. Cake treatment can, for instance, comprise single- or multi-stage cake washing and subsequent cake drying. Cake discharge can take place at atmospheric pressure. Application scenarios cover a wide range of industries, including industrial chemicals, fine chemicals, the pharmaceutical industry and the food industry.

Versatile technology solutions

The rotary pressure filter supports a broad range of process steps during a single rotation of the drum. After separating the suspension into filtrate and filter cake, the rotary pressure filter supports the following additional processes: single- or multi-stage cake washing, displacement washing, counter-current washing, circulation washing, slurrying, solvent exchange, steaming, extraction, as well as mechanical or thermal cake dehumidification. All process steps take place in separate segment zones within the filter. This makes it possible to separately discharge the filtrates or other substances.

Closed, gas-tight method of operation

The rotary pressure filter is a fully encapsulated unit that can be integrated into production processes in a gas-tight manner. This means that the rotary pressure filter is also suitable for use in operating scenarios with increased safety or hygienic requirements.

Variable process pressures and temperatures

The rotary pressure filter operates at a pressure of up to 7 bar (g) and within a temperature range of approx. -20° to approx. 160° Celsius. During all process steps, pressure is generated hydraulically via the inlet pipes for the suspension or washing/extraction media rather than pneumatically by means of gas stratification. This enables the procedural optimization of each individual process step.

Cake discharge at atmospheric pressure

Each process step is sealed off into a segment zone by means of pressure-tight separation elements inside of the rotary pressure filter. The cake can be discharged to the surrounding area at atmospheric pressure.

Materials

We utilize different stainless steel grades as required by the specific application scenario. We employ high-quality sealing materials and advanced plastics suitable for each application.

ATEX

We are ATEX certified. We produce special-purpose filters for applications in the pharmaceutical, food and bioprocess industries.

Performance Data, Dimensions, and Weights

| TYPE | DRUM DIAMETER | EFFECTIVE DRUM LENGTH | ACTIVE FILTER AREA | DIMENSIONS (L X W X H) | WEIGHT |

|---|---|---|---|---|---|

| RPF P01 | 0,75 m | 0,1 m | 0,18 m² | 2 x 1,2 x 2m | 2.500 kg |

| RPF P02 | 0,75 m | 0,25 m | 0,45 m² | 2,1 x 1,2 x 2 m | 3.500 kg |

| RPF A03 | 1 m | 0,3 m | 0,72 m² | 3,9 x 2,1 x 2,2 m | 7.000 kg |

| RPF A06 | 1 m | 0,6 m | 1,44 m² | 4,2 x 2,1 x 2,2 m | 10.000 kg |

| RPF A09 | 1 m | 0,9 m | 2,16 m² | 4,5 x 2,1 x 2,2 m | 13.000 kg |

| RPF A12 | 1 m | 1,2 m | 2,88 m² | 4,8 x 2,1 x 2,2 m | 15.000 kg |

| RPF B09 | 1,5 m | 0,9 m | 3,2 m² | 5 x 2,9 x 3,2 m | 20.000 kg |

| RPF B12 | 1,5 m | 1,2 m | 4,3 m² | 5,4 x 3 x 3,2 m | 30.000 kg |

| RPF B16 | 1,5 m | 1,6 m | 5,8 m² | 5,8 x 3 x 3,2 m | 35.000 kg |

| RPF X16 | 1,8 m | 1,6 m | 6,9 m² | 5,8 x 3,3 x 3,6 m | 40.000 kg |

| RPF X20 | 1,8 m | 2 m | 8,6 m² | 6,2 x 3,3 x 3,6 m | 42.000 kg |

All specifications apply to a high-performance filter with Center Drive. The shown dimensions an geihts are approximate figures.

The technical data for other designs may vary from the information shown here.

All technical data may change due to development.

Subject to modification without notice.

| Operating method | continious |

|---|---|

| Operating pressure | up to 6 bar (g) |

| Operating temperature | up to 160° C |

| Soldids content (suspension) | up to 60 % (by weight) |

| Cake thickness | up to 175 mm |

| Grain size | 10 - 500 µm |

| Filter output – suspension | up to 30 m³/m² h |

| Filter output – dry solids | up to 15.000 kg/m² h |

| Active filter surface | 0,18 - 8,6 m² |

73 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT