- Novo

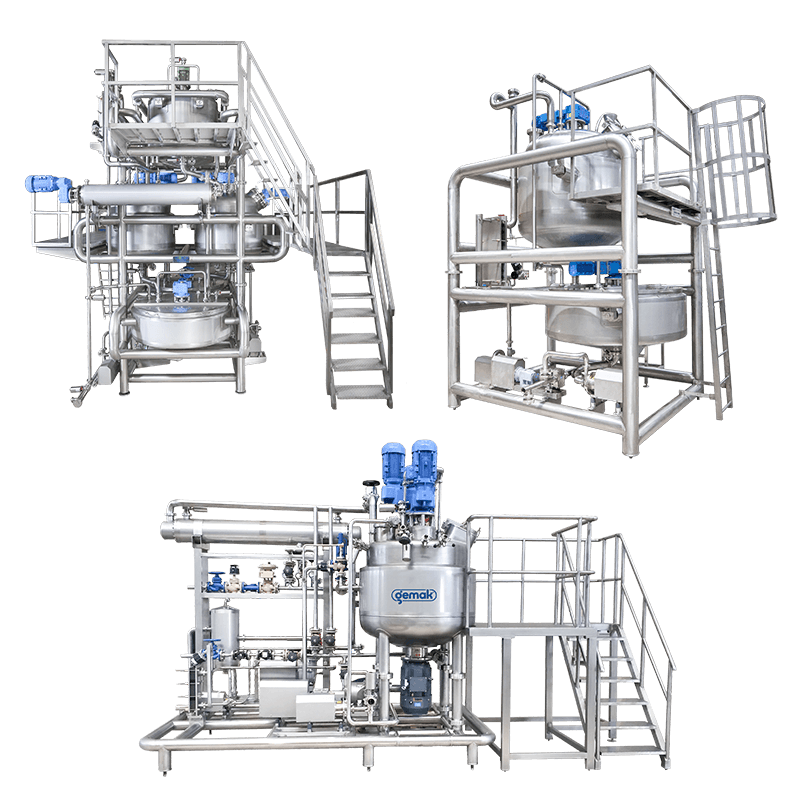

Vacuum Cooker

Gemak Cooker makes high quality production with high quality equipment, full automation and extra hygienic system.

Descrição

The unit includes preparation, cooking, and holding-cooling parts. Products are weighed, transferred and mixed according to recipe in the preparation stage.

Prepared mix is transferred to the tank underneath the preparation unit.

The mix is cooked under pressure, Brix and temperature are controlled, if the mix is in requested condition, it is transferred to holding-cooling tank underneath this section.

Products are cooled to the required temperature and then transferred to the storage tank. The system works with full automation. Manufactured in one frame which made of AISI 304-316 stainless steel.

Technicial Specifications

- Vacuum system provides cooking at low temperature to avoid the loss of color, taste, and aroma of the product

- Specially designed for medium and heavy applications in the bakery and confectionary

- Gentle processing of viscous and heat sensitive products

- High level of hygienic design and manufacturing

- Designed and manufactured according to EHEDG guidelines

- Different configuration and layout setup per customer request or process requirement

- Product wetted parts can be AISI 316L or AISI 304L

- High efficient and less energy consumption during mixing and cooking

- Batch process or continuous operation.

- Variety of mixers and agitators (paddle, propeller, anchor, gate, scrapper, etc.)

- High shear mixer for homogenization and lump-free dispersion of ingredients

- The system can optionally include a high shear mixer for emulsification or rehydration

- High precision dosing of liquid and powder ingredients by flowmeters or loadcell

- Aeration unit for density reduction for aerated and soft products

- The system can be equipped scraped surface heat exchanger for faster cooling

- Integrated Brix meter for continuous brix monitoring

- Fully CIP-able design and integrated CIP software

- Rotary lobe pumps for viscous and foamy product transfer

- High efficient condensation unit with Alfa Laval Heat Exchanger and vacuum pump

- Accurate control of temperature, vacuum, and mixers allowing consistency and reproducibility of the final product

- User-friendly HMI screens and easy to use software

- PLC controlled fully automated user-friendly system

- Recipe management system

- Internet connection for remote access

- Open-source software

- Premixing unit (integrated/unintegrated) that shortens batch time

- PED certification

Application Areas:

- Jam and Derivatives

- Marshmellow

- Invert Syrup

- Caramel

- Sauce

- Milk and milk products

- Food industry

- Cake

- Cream

- Pudding

- Mayonnaise

- Sauce

- Marmalade

16 outros produtos na mesma categoria:

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT