- Novo

PASTRY MAKE-UP LINE

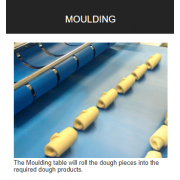

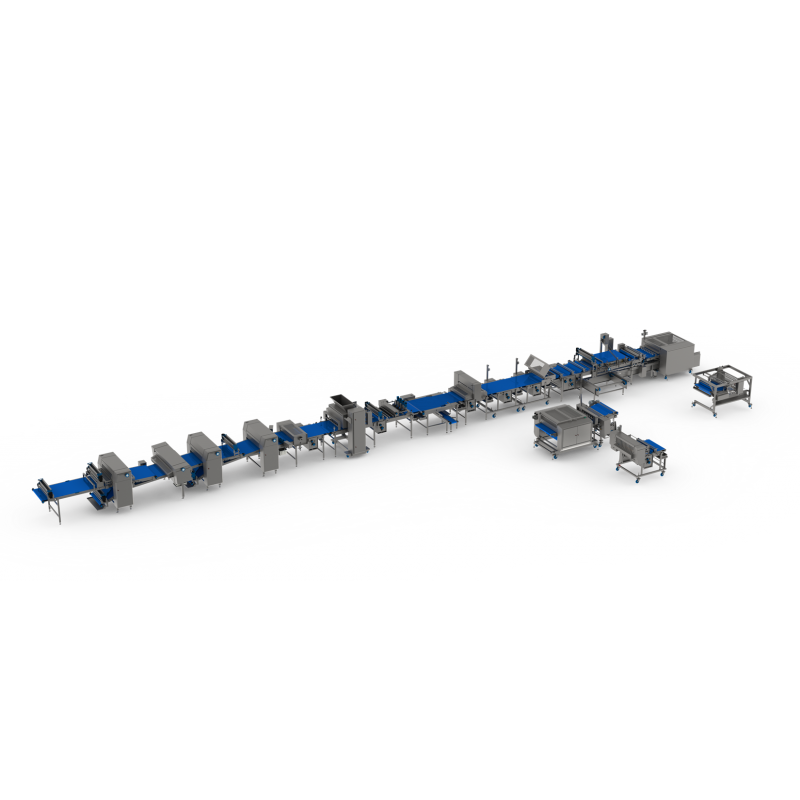

With our Pastry make-up line you can produce all kinds of pastries and laminated products in any shape and size, unfilled or filled with the finest sweet or savory fillings.

Descrição

Our pastry make-up line is developed to produce a wide product variety for semi-industrial to full industrial bakeries. Capacities depending on product size and weight, but non-stop production of large quantities at high speed with superb product quality is guaranteed. The pastry production machine features a flexible and modular design. It always combines the best possible product quality with an optimal capacity, quick product changeovers, low maintenance and superb hygienic characteristics.

WORKING WIDTHS

› 600 mm

› 800 mm

› 1,000 mm

› 1,200 mm

› 1,400 mm

› 1,600 mm

Power to the pastries

Pastries are increasingly popular at the breakfast table or as an in-between snack. In any shape or size, pure or filled with the finest chocolate or preserves, all pastries and laminated products can be shaped by the Universal Make-up line developed by Rademaker. This production line will allow you to form and shape dough (mostly laminated dough) into high-quality pastries, just the way you want it in large quantities (for midsize to industrial bakeries) and with a superb product quality. The Rademaker Universal Pastry line can handle a large variety of dough types with a broad range of shapes and sizes.

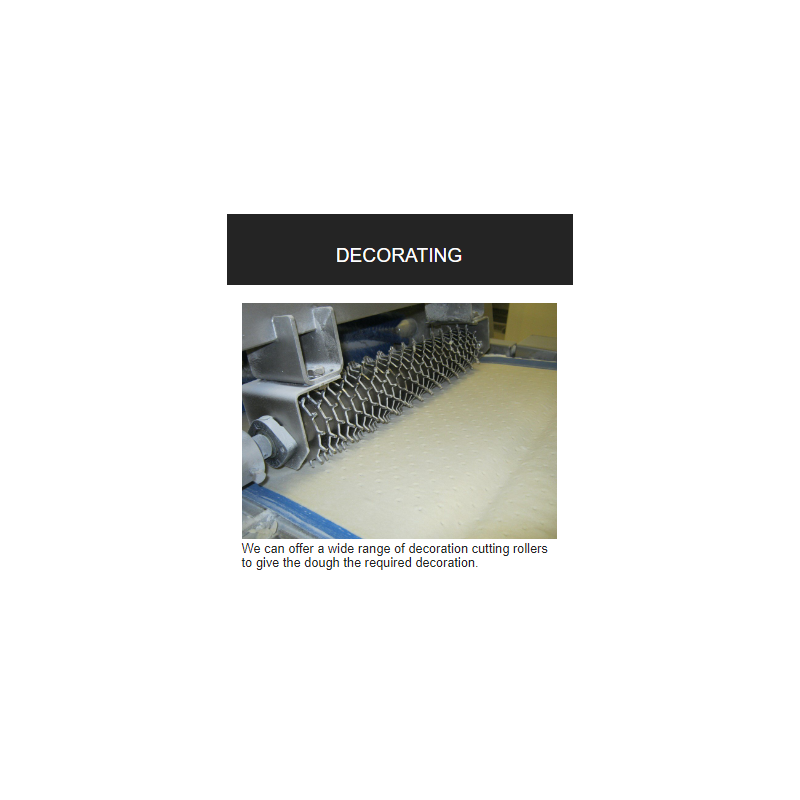

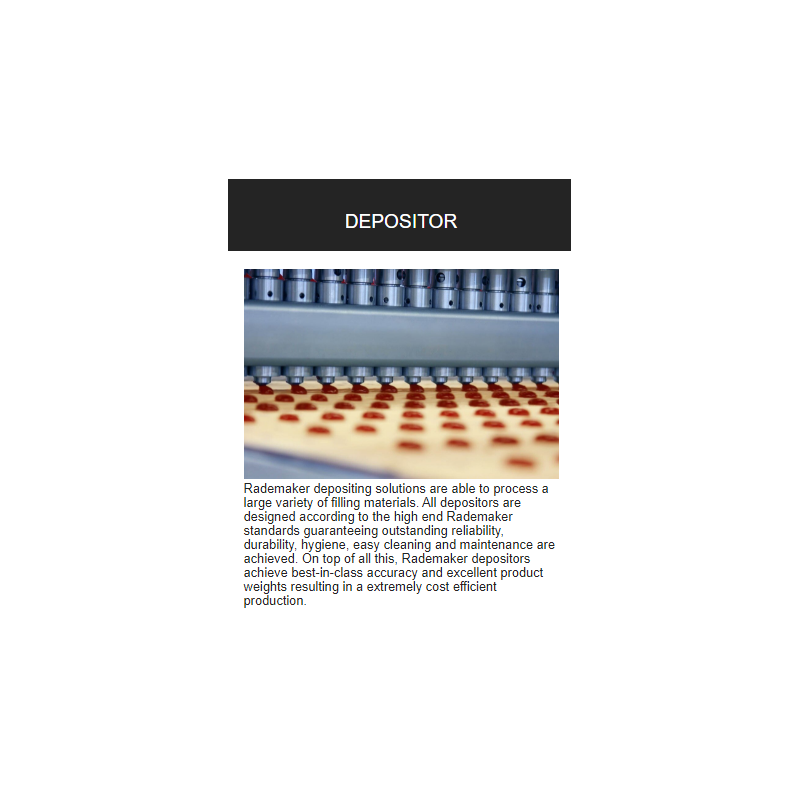

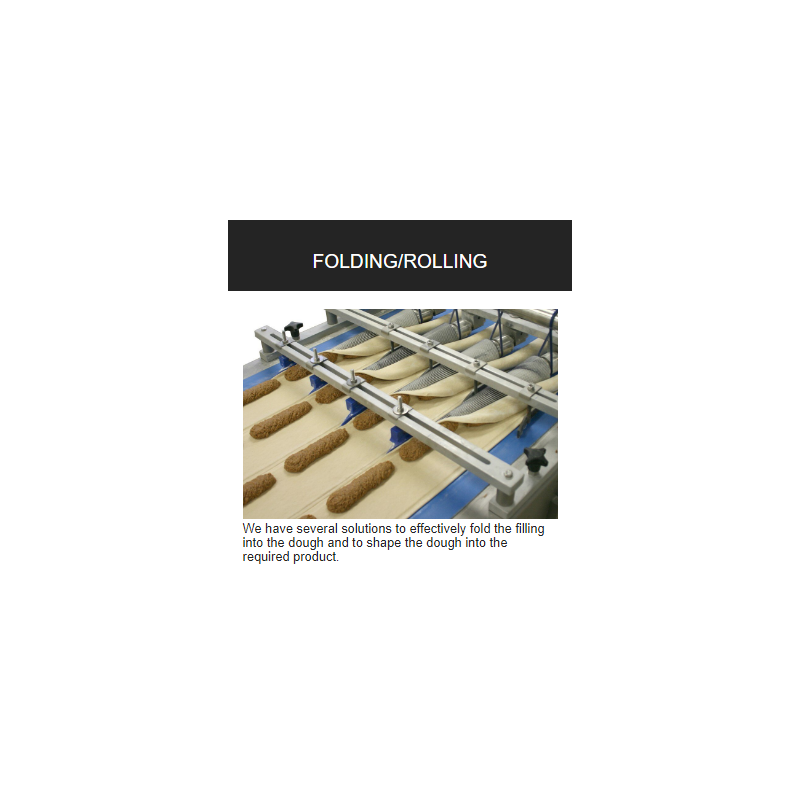

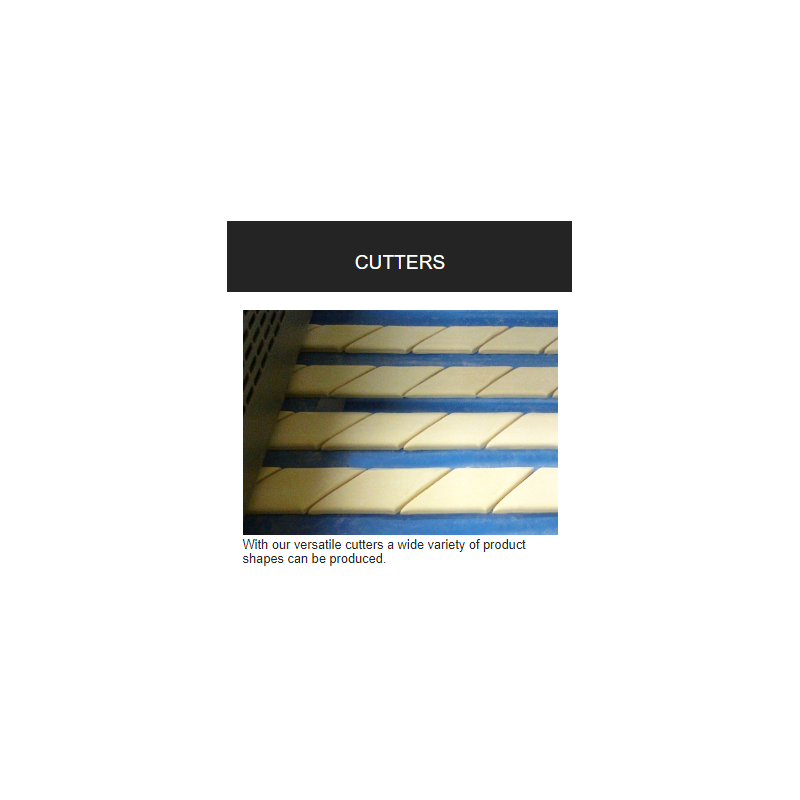

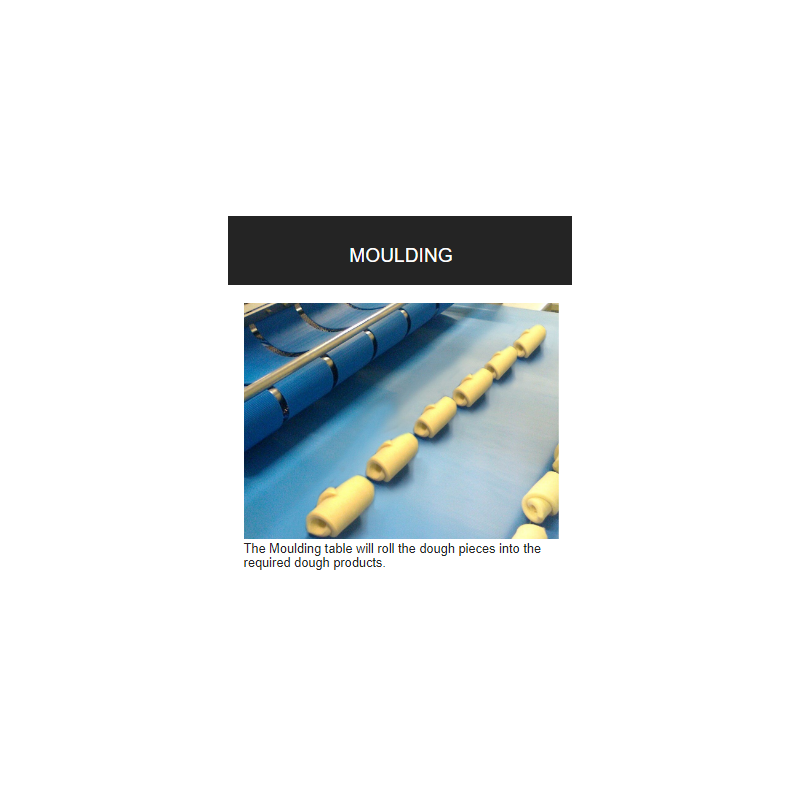

The Universal Pastry line’s working width ranges from 600 - 1,600 mm. The line can be equipped with a wide variety of options to shape your dough. To add to its versatility, the line can also be equipped with numerous tools, that are designed for fast and easy change-over, including flour removal brushes, circular cutters, rolling-folding-shaping equipment, guillotine cutting knives, stamping tools or even high-speed horizontal guillotines. Decorating by means of depositors, egg yolk or water spraying systems, universal dispensers or a fruit and cheese applicator is possible as well. Each operation is carried out automatically. The line is capable of non-stop production and the capacities depend on the customers’ requirements. After shaping, the products can

be transferred automatically to a proofer, a freezer or baking trays using a retracting belt or in-line tray loading.

110 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Novo

- Novo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Novo

- Novo

- Novo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT