- Novo

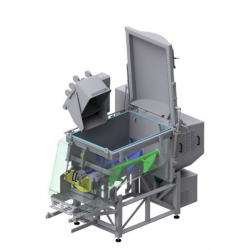

Mixing System

Contract price

Mixing systems from endeco ensure gentle mixing at high speeds

UPC:

EAN13:

Descrição

Mixing systems from endeco ensure gentle mixing at high speeds – it pays off! We will implement a mixing system that is optimally tailored to your needs and we pay special attention to your unique requirements.

Endeco quality in development and implementation

Let our many years of experience in the development and implementation of mixing systems contribute to your success.

- Ideal mixing solutions for the foodstuff, plastics, and chemical industries

- Individually designed and implemented, tailored to your products and spatial conditions

- Conveyor and dosing devices as well as the mixing process are selected based upon the required mixing quality and accuracy

- Extensive product database for bulk materials (incl. flowability, product/product and product/wall friction angle etc.), scientific examination of unknown products, if necessary

Even high differences in density and grain size are no problem for your endeco mixing system - Vertical or horizontal mixers

- Gentle mixing with shortest possible dwell time

- Almost complete emptying of the mixer – for quick product changeover and easy cleaning

- Continuous or discontinuous mixing processes

- Gravimetric weight measurement via load cells possible

Tailored to your needs – designs and options:

- Designed according to ATEX requirements in zone 20/21/22

- Material S235 JR or stainless steels 304 or 316L

- Compliant with GMP, FDA, and EU 1935

- Custom surfaces from mill finish to ground and polished

- Wear-resistant design possible

- CIP and SIP systems can be integrated

- Explosion-proof design

- Direct filling via pneumatic pressure, sender, or suction conveyors as well as big bag and sack emptying systems

- Adaptation to existing buildings

- Filter systems for dust recirculation integrated in the process – for minimized material loss during filling and emptying

184 outros produtos na mesma categoria:

- Novo

MIXWORKING BATCH - PASTEURISING PLANTS

- Novo

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- Novo

Blending system Innopro Paramix C

- Novo

Vertical Spindle Dough Mixer 550

- Novo

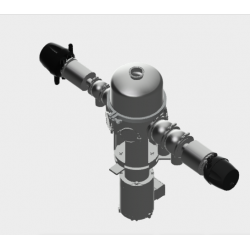

DLM/FS Solid-Liquid Inline Mixer

- Novo

Overturnable Mixer NUOVA VITTORIA

- Novo

CHOCOCON 150 chocolate / compound processing unit

- Novo

PREMIX FOR WINE AND GRAPE JUICES

- Novo

Dough-kneader machine МТ-300 K.423

- Novo

Mincer mixer AK-RAMON PM-32 PM-114

- Novo

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- Novo

Coating and Enrobing machines

Continuous drum coating machine for adding spices and flavors AD

Preço

8 900,00 €

- Novo

MIC Turbo – Mixer Granulator – Food

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT