- Novo

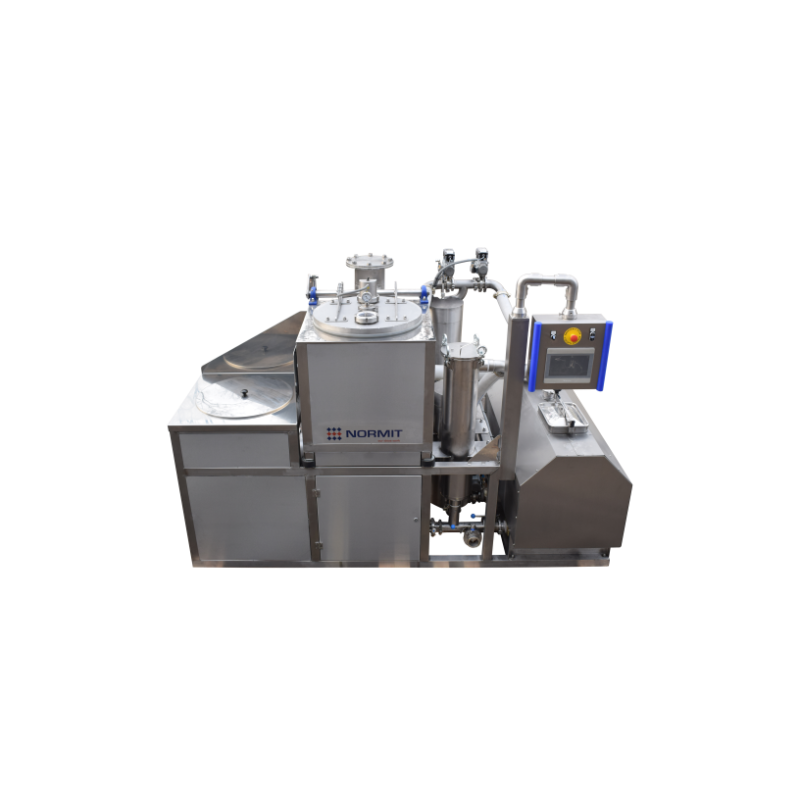

Vacuum fryer with blancher

Frying – under vacuum conditions (at low temperature) – is a unique and modern way of heat treatment, allowing to achieve the unique properties of the finished product.

Descrição

The NORMIT vacuum fryer allows frying the product to a crisp state at temperatures up to 120 ° C without acrylamide formation *. The fried product does not contain carcinogenic substances and is a healthy alternative for most snacks on the market.

We produce vacuum fryers from 20 to 350 liters.

The water is removed under vacuum conditions in a very short time, in addition, under vacuum conditions, the oil does not penetrate into the released pores, complete oil removal is carried out while maintaining the vacuum, allowing the oil content of the finished product to be reduced, while during traditional frying under atmospheric pressure, the oil content can reach 30%.

Depending on the product and its pre-cooking (blanching, soaking, freezing), there is the possibility of obtaining products with different properties – with a more or less dense structure (puffed snacks), more crunchy or softer with different color intensity and the like.

* Acrylamide is a low molecular weight, highly water-soluble organic compound that arises from the naturally occurring components of asparagine and sugars in certain foods when prepared at temperatures usually above 120 ° C and low humidity. It is mainly produced in baked or fried carbohydrate-rich foods whose raw materials contain its precursors, such as grain, potatoes and coffee beans.

Some types of products need to undergo additional processes before vacuum frying such as starch washing, soaking, freezing, but blanching is most often applied before frying or drying.

Short-term blanching in hot water makes it possible to significantly increase the useful characteristics of the finished product by deactivating the enzymes. It improves the external appearance of the product, obtains a brighter color, intensifies the taste and smell (they are not destroyed during frying).

The design of the NORMIT vacuum fryer consists of the following main parts

Blanching chamber

Vacuum frying chamber

Oil heating system

Vacuum container for oil storage and forced oil cooling

Vacuum oil removal system

Vacuum generation system

Oil filtration and oil circulation system

Rotary lifting device (optional)

The construction of the vacuum fryer with blancher is compact, all units are placed on one frame and do not need additional assembly and extra control panel.

The volume of the blanching chamber corresponds to that of the frying basket. No need to reload (from basket to basket). The product first goes through blanching, then, after draining, is immersed in a frying chamber. Optionally, the vacuum fryer may be equipped with a rotating lifter that allows the product basket to be easily lowered into the blanching chamber, then lift the basket to drain the water and then transfer and immerse it in the frying chamber.

Počas vákuového fritovania, sa nasledujúca várka produktu blanšíruje a odteká, čo umožňuje dosiahnuť polo-kontinuálny spôsob výroby.

During vacuum frying, the next batch of product is blanched and drained, allowing a semi-continuous process to be achieved.

Automatic control system

The vacuum frying / drying process is quite complicated in the sequence of processes carried out, therefore the NORMIT vacuum fryer / dryer is equipped with a fully automatic control system with different formulas, minimizing demands on the operator and eliminating human factor errors.

All executed processes are displayed in the operator panel (process visualization). New recipes are programmed using an intuitive interface.

Benefits

Possibility to produce a wide range of products: Fruits (bananas, apples…), vegetables (potatoes, carrots, beets, parsnips and others), meat, fish

Full preservation of useful properties of raw materials, vitamins and minerals.

Intensify the natural taste and aroma without adding artificial ingredients.

The automatic recipe management system allows you to fry different products in different modes without having to adjust.

The oil used in the frying process is not exposed to high temperatures, does not burn, does not absorb odors and color pigments and can be used for frying and drying various products without having to change it.

Highest energy efficiency – without energy losses.

In the room where the drying happens, no undesirable odors (product, smoke) and vapors are produced.

The vacuum dryer / fryer equipment currently provides the most modern preservation method.

The vacuum frying / drying system is absolutely hermetic – free of smoke, oil mist and odor.

The device is compact, constructed on a single frame and requires minimal on-site assembly (transported assembled).

Fast loading – additional baskets (optional) are filled with product during frying of previous batch.

Thanks to the divided basket, the whole volume of the product is divided in height, there is no pressing of the product and it guarantees its even processing. Such a design also makes it possible to process different products simultaneously (with the same processing mode), while the aroma, taste and color of each product is maintained and it is not mixed with others.

To operate the device, it is necessary to connect to a source of thermal energy (electricity / steam or gas), electricity, compressed air and a source of cooling water. Chiller can be included as an option.

39 outros produtos na mesma categoria:

- Novo

Modular Electric Compact Conveyor fryer 400/1100/12

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT