- Nuovo

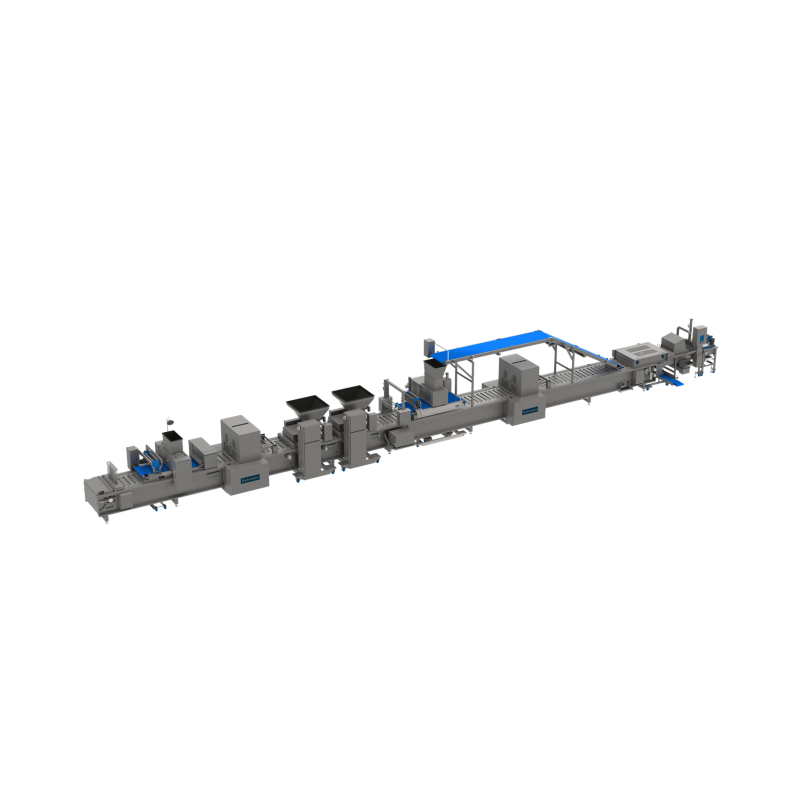

PIE/QUICHE LINE

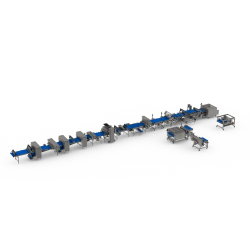

With the pie production equipment from Rademaker you can count on the production solutions for your specific needs.

Descrizione

We are a true specialist in food processing equipment and we support your production process any way we can. Produce pie and quiche in varying sizes with our production equipment.

CAPACITIES OF OUR PIE PRODUCTION EQUIPMENT

Production capacity varies per size, dough type and filling but ranges from 5,200 pieces/hour (250 mm diameter product) to 20,000 pieces/hour (80 mm diameter product). Capacity up to 40,000 pieces/hour can be reached in tandem execution. Production is possible in aluminum foils, paper containers, metal baking trays, indented baking trays and pre-moulded baking trays. Product diameters range from 50 to 282 mm.

WORKING WIDTHS

- 600 mm

- 800 mm

- 1,000 mm

- 1,200 mm

The prodcution process of our Pie/Quiche Line consists out of the following processes:

- The conveyor is either applicable for platens or baking trays. The conveyor is also suitable for the dosing of cupcakes, cheesecakes etc.

- The foil denester is provided with a vacuum system to ensure that the foil is correctly placed.

- Dough processing: the Rademaker stripfeeder and the guillotine ensure very accurate dough weight

- The dough billets are blocked to the desired shape without any scrap by a servo driven press. The blocking head is water heated for a precise and reliable operation.

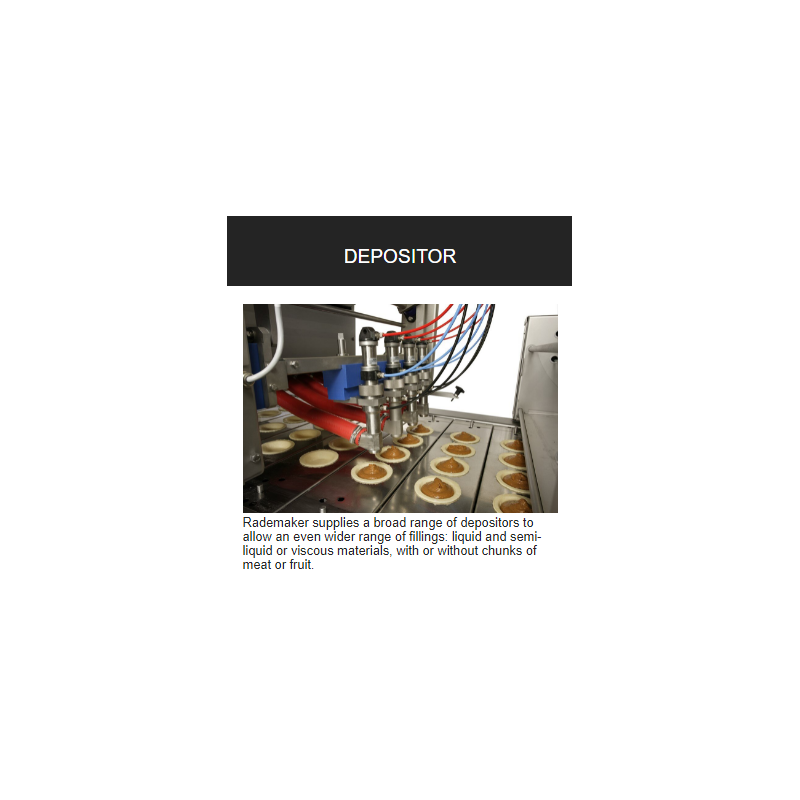

- Rademaker supplies a broad range of depositors to allow an even wider range of fillings: liquid and semi-liquid or viscous materials, with or without chunks of meat or fruit.

- If a lid is desired for the product, an extruder can be one of the options.

- Optionally you can integrate a lattice unit to the Pie line.

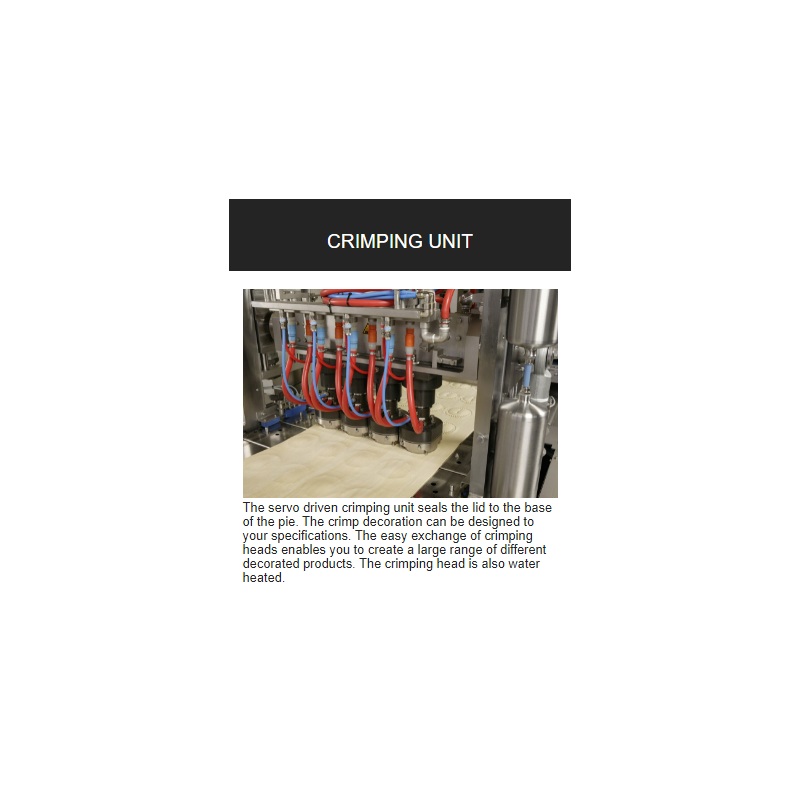

- The servo driven crimping unit seals the lid to the base. The crimp decoration can be designed to your specifications. The easy exchange of crimping heads enables you to create a large range of different decorated products. The crimping head is also water heated.

- The outfeed system transfers the pies from the conveyor towards dedicated panels but can also be delivered with a set-up for

offload to oven band, freezer infeed or trays. - Additionally an eggyolk sprayer can be installed. Optionally with air-knife for blow off of excess glaze.

- Another installation option is a strewing unit. Various dry toppings can be applied onto top of the pies.

- To optimize the oven or freezer loading a “marshalling” unit can be used. This unit enables you to increase the number of rows across the width on the following conveyors.

Wide assortment of products

With the Rademaker Pie/Quiche line you can make any products you desire. With the Rademaker depositor-range you can fill your pie or quiche with any kind of filling. While our Pie/Quiche line is developed to produce an extensive and international assortment of pies and quiches, we can take the extra step and apply one of the major strengths of Rademaker, namely developing customized modules tailored to your specific needs. On this pages an overview of some products that our line can make.

110 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuovo

- Nuovo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT