- Nuovo

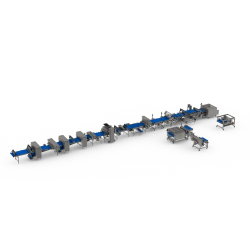

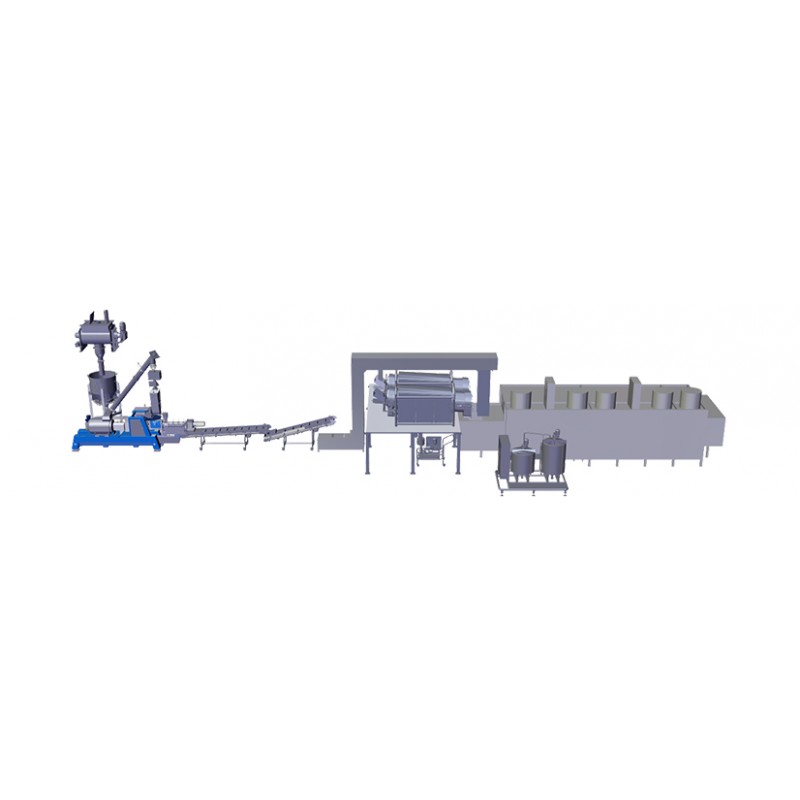

BREAKFAST CEREALS PRODUCTION LINES

Our twin-screw extrusion lines produce expanded ready-to-eat breakfast cereals

Descrizione

Our twin-screw extrusion lines produce expanded ready-to-eat breakfast cereals which are natural, coated or filled with a wide variety of recipes and shapes.

Twin-screw extruder is at the core of this very flexible and scalable manufacturing process. To meet market demand and manufacture new products, our food production lines are easily changed and adapted using simple add-ons, making it possible to manufacture bicolor or filled cereals, as well as flakes.

HOW DOES BREAKFAST CEREAL PRODUCTION LINE WORK?

After preparation, controlled quantities of raw materials and liquids are premixed and then dosed before being fed continuously and uniformly into the extrusion platform. This mixture is then cooked at the right temperatures using the thermo-mechanical energy provided by the twin-screw extruder. Texturing and shaping of expanded products are determined by the final design of the insert, while the expansion ratio is influenced by temperature of the extrudate, the types of ingredients used and moisture content.

The shaped products are then conveyed directly to the sugar coating system. The coated cereals are dried and cooled down to ambiant temperature to retain crispness, as defined in the recipe. The products can also be filled when the unit has a co-extrusion add-on.

The added value of your breakfast cereal production line :

• Productivity: continuous and automated process starts and quick stops, fast and easy changeovers and ease of cleaning and maintenance

• Flexibility, enabling product innovation:

A great variety of raw materials for processing a wide range of cereals

A vast choice of sizes, shapes and fillings (with optional co-extrusion add-ons)

The possibility of extending the range of products by simply adapting modules or adding components to produce flakes, bicolor products, co-extruded cereals with visible inclusions or varied shapes.

• Cost-effective: intensified HTST (High Temperature Short Time) transformation process, generating savings in raw materials, as well as energy and water; easy maintenance, hygienic design and compact design requiring less floor space.

• Expert systems: specially designed by our specialist engineers, with advanced automation to ensure precise process control for consistent product quality that can be easily replicated.

• Finished product capacity : 200 kg/h to 2000 kg/h

110 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT