- Nuovo

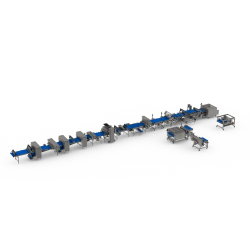

Food Vitaminization

Enriching the food with vitamins is a new way of presenting powdered products, whereby manufacturers are adding nutrients to their traditional formulas.

Descrizione

Vitamins are heterogeneous compounds with no energy value. Since they cannot be synthesised by the body, they can only be incorporated through direct intake. These nutrients are essential for life, in the same way as proteins, carbohydrates and minerals.

However, excessive intake can result in illness (hypervitaminosis) thus it is essential to ensure an "excellent dispersion" of these particles throughout the raw materials to be mixed. In this way, the consumer is guaranteed to receive the correct dose in each packaged product.

The MIC machines perfectly perform this process even with the most demanding products, such as active ingredient dispersion in the pharmaceutical sector. The assurance of achieving "one part per million," makes this technology the leader in mixing processes for those companies who seek quality and excellence.

Features

PC with colour Touch-panel screen.

Smart raw material ID.

Smart operator ID.

Process editing system for each product.

Vacuum filling system.

Agglutination injector vessel.

Peristaltic pump with volume control.

Automatic cut-off by means off torque measurement.

Curve tracing.

Printed reports.

Remote on-line help.

Automatic cleaning system.

Electrical system in accordance with ATEX rules.

IN WALL/recessed installation.

Manufactured according to GMP guidelines.

Software in accordance with FDA 21 CFR part 11.

FAT/SAT validation documents.

Furthermore, the efficacy and safety of the cleaning process, due to the absence of “dead spots” or inaccessible areas allows for the use of different products without the risk of cross-contamination.

Our development and research lab offers our customers the option to produce product volumes as low as 1 litre using the same technology as the industrial machines, making them into scalable developments.

Our qualification and validation department provides our customers with the ability to validate their production processes by issuing documents that can be submitted to the corresponding authorities.

These comply with GMP and FDA guidelines, for both their construction and software applications.

110 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Nuovo

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Artificial Rice Extruding Line / Instant Rice Making Machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT