- Nuovo

- Nuovo

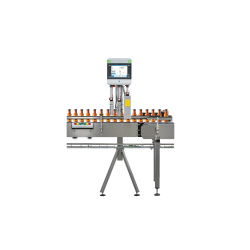

RAYCON D+ x-ray product inspection system

Intelligent x-ray product inspection system for packaged products – End of line inspection.

Descrizione

Intelligent x-ray product inspection system for packaged products – End of line inspection.

- Longer lifetime of core components

- Application variability

- Surpassing detection requirements

- Increased ease of use

Performance features

The RAYCON D+ product inspection system detects all contaminants that due to their density, chemical composition, or mechanical dimensions absorb x-rays better than the surrounding product.

With its optional capability using Dual-Energy technology the performance for soft contaminants gets extremely improved for materials e.g. types of plastics (PVC, aso.), rubber, ceramics, stones, calcified bones and similar materials.

The RAYCON D+ product inspection system is characterised by the following performance features:

- Throughput: ~250 pcs./min. (product specific)

- Detection capability starting from Ø 0,3 mm

- 200W long life x-ray generator

- Highest operator safety due to low x-ray emission < 0.5 µSv/h

- Modular and stable frame design allows easy transportation and safe installation

- Ambient temperatures from 0°C to + 40°C

- IP 66 protection class within conveyor area

Longer lifetime of core components by Intelligent Power Management (IPM)

- Automatic detection of product height

- Automatic power adjustment of the x-ray source

- Extended lifetime of x-ray source

- Increase of energy efficiency

- Maximum sensitivity without special settings

- Time savings during the learning process of the different products

Application variability

- The modular design allows adaptation to various applications

- Depending on machine configuration, foreign bodies are detected from 0,3 mm

- Modular principle enables fast, uncomplicated and cost-transparent upgrade

- Platform concept enables subsequent update

- Easy to clean due to hygienic design

- Tool-free belt change within 2 minutes

- HD (High Definition): Detects foreign bodies from 0,3 mm (e. g. stainless steel, steel, copper, glass, ...)

- Dual Energy: Detects soft impurities from 2,0 mm (e. g. bones, rubber, ...)

Surpassing detection requirements

- Surpasses the latest and most valid food regulations by up to 400%

- False reject rate (F.R.R.) below 0,01%

- The system detects products up to a conveying speed of 1 m/s

- Maximum throughput is 250 pieces per minute

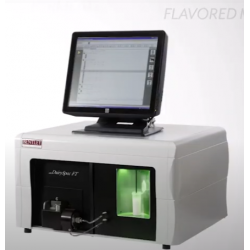

Increased ease of use

- The 15 "HD touch display in 16:9 format offers a high resolution for excellent picture quality

- No special operating knowledge is necessary

- Automatic recognition of the product packaging by the edge filter

- Minimizing the frequency of false rejects and product wastage

- Automatic detection of the x-ray source lifetime and early warning by the system

- Warranty extension from 3 to 5 years through the optional service package

Important information:

X-radiation is classified as ionising radiation. However, X-radiation is not radioactive radiation! In accordance with EU directive 1999/2/EC, Sesotec x-ray systems due to the minimum radiation energy can be used for the contaminant inspection of food materials even with organic products. The RAYCON product inspection system is subject to the German x-ray ordinance and requires certification. Please observe any country-specific regulations!

77 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT