- Nuovo

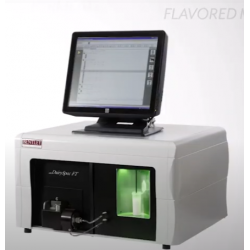

HEUFT eXaminer II XB

Simply detecting more: top-down inspection with pulsed X-ray technology based on the HEUFT SPECTRUM II.

Descrizione

The HEUFT eXaminer II XB achieves simply more when specifically detecting solid foreign objects in packaged and unpackaged food: the unique combination of pulsed X-ray technology and full-field image converters carries out a careful top-down inspection with a new dimension in precision, flexibility and range with maximum operational reliability. The continuous examination of particularly large-sized products with a minimum amount of radiation is accomplished simply safely. The high level of automation of the HEUFT SPECTRUM II device platform and the self-explanatory HEUFT NaVi user guidance make the error-free operation of the end of line system simply easy.

Foreign object detection

Maximising detection reliability: top-down inspection with unique pulsed X-ray technology.

Glass, metal and stones: foreign objects such as these have as little place in flow packs, thermoform packaging, pouches and composite packages as in solid products or food jars. The HEUFT eXaminer II XB finds them! A unique combination of X-ray strobes, compact full-field image converters and HEUFT reflexx² image processing, available exclusively from HEUFT, ensures the maximum range, speed and precision of the top-down inspection.

Larger sized products can be examined continuously and with high precision due to the large, sensitive detection surface. Even the border areas of the extremely clear X-ray images remain free of distortions and aberrations. The low radiation level is unequalled. It is emitted as X-ray flashes which only last a thousandth of a second. In addition this prevents motion blurs at line speeds of up to 1,200 products per minute and therefore ensures maximum detection accuracy.

The inspection of product and packaging

Simply detecting more: the detection of damaged and incomplete products.

Defective, incomplete products and missing packaging components: the HEUFT eXaminer II XB also identifies such faults using pulsed X-ray technology and full-field image converters with an unprecedented precision. The HEUFT reflexx² real-time image processing system with teaching in capability clearly differentiates between real faults and harmless product inhomogeneities and packaging structures in the course of this.

This is also achieved reliably in the case of oversized products due to the extended sensitive detection surface. In contrast to metal detectors neither the product's own signal nor metal packaging components can impair the detection reliability.

A static inspection is also possible because there is no permanent beam emitted but merely X-ray flashes only lasting a millisecond. The product can also be precisely examined when the conveyor is not moving e.g. for internal quality assurance purposes.

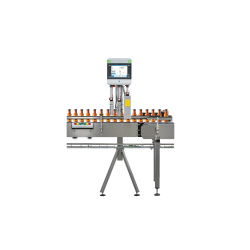

Fault rejection

Preventing recalls: the reliable rejection of faulty containers.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The single-segment and multi-segment rejection systems of the HEUFT rejector series deal with this both precisely and carefully.

77 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT