- Nuevo

Type F-560

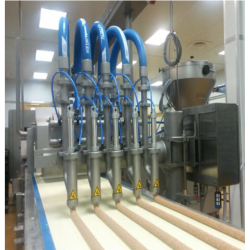

The F-560 filling system ensures the accurate distribution of the portions from the multihead weigher to the trays on the single our double lane conveyor.

Descripción

Suitable for single or double lane filling

High capacity while maintaining a manageable filling pattern

Easily exchangeable tooling for quick changeover times

Filling system, type Tramper F-560

Servo controlled filling

The F-560 filling system ensures the accurate distribution of the portions from the multihead weigher to the trays on the single our double lane conveyor.

A servo driven swiveling funnel distributes the portions between the buffer hoppers. From the buffer hoppers, the portions are transferred into the filling hoppers. The filling hoppers are then positioned horizontally (servo controlled) above the trays on the transportation system. When the trays are ready on the transportation system, the filling hoppers are positioned just above or into the trays with a vertical movement. Next, the filling hoppers are emptied and the product is (optionally) pressed into the tray with a servo controlled pressing/tamping unit. Then a new cycle starts again.

The tooling is very easy to change. This makes a quick changeover between different tray sizes possible.

The machine is extremely suitable for single or double lane filling of solid products, such as (mixed) vegetables, mussels, shrimps, olives, nuts, chicken fillets, meatballs and other food types.

Features of the F-560

Easy to clean

Filling range

High capacity

easy to clean thanks to its hygienic and accessible design

600x500x130, suitable for single and double lane filling

high capacity while maintaining a manageable filling pattern

Specifications of the filling system

Version: single or double lane

Product supply points (weigher): 1 or 2

Filling points: 2 - 12 (depending on tray size)

Portion size: 30 – 4000 grams

Filling range: standard 600 x 500 x 130 mm (LxWxH)

Capacity: up to 18 cycles per minute (product dependent)

Can be equipped with an integrated pressing/tamping system

Optionally equipped with a reject hopper for discharging incorrect weights or remaining product at the end of a batch

220 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

TPM 1000 fully automatic thermoforming packaging machine

- Nuevo

- Nuevo

GF series automatic plastic bottle filling and capping production line

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Vertical form-fill and seal machine of the “Economy” series

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

AUTOFLOW Automatic Bag in Box and Stand Up Pouch Filler

- Nuevo

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Filling and seaming groups for aluminium and tin plate cans

- Nuevo

- Nuevo

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- Nuevo

DABL series automatic aseptic plastic bottle filling and capping machine

- Nuevo

- Nuevo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT