- Nuevo

- Nuevo

HEVF - Electronic volumetric filling system

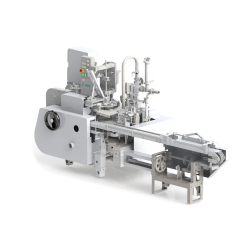

The filling machines of the renewed HEVF series, manufactured according to the new HYPER CLEAN characteristics.

Descripción

The filling machines of the renewed HEVF series, manufactured according to the new HYPER CLEAN characteristics, are suitable for the VOLUMETRIC filling of flat products in PET bottles.

HEVF fillers are characterized by:

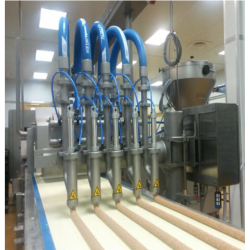

- high precision flow meter installed for each filling valve;

- simplified filling valve, with reduced number of gaskets, capable of managing two filling stages (slow filling and fast filling);

- no contact between filling valve and bottle during the filling;

- reduction of costs and time dedicated to maintenance;

- wide range of filling products thanks to the interchangeable valve terminal, dedicated to each type of product.

The machine is complete, in the basic version, also with the following features:

- 7 ”HMI (15” HMI available as an optional);

- parameters of each format to be directly managed through HMI;

- quick changeover of the bottle guide equipment;

- dummy bottles with hand-operated set up to ensure complete cleaning and sanitization of the parts in contact with the product (dummy bottles with automatic set up available on request);

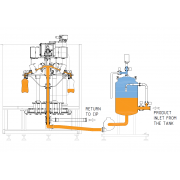

- product pump to maintain constant pressure during filling;

- compact frame for space saving in the filling line and reduced transport costs.

Available in various sizes to cover a wide range of production, the machines of the HEVF series are available in the filler/capper, rinser/filler/capper versions or in the innovative ECOBLOC® version where the ENOBERG filler-capper block is combined with the SMI stretch-blow moulder.

PRODUCTION RANGE

|

PRODUCT |

SPEED (bph) |

REFERENCE |

||

|

Flat water |

1.000 – 48.000 |

0.5 lt |

||

|

Isotonic drink |

1.000 - 35.000 |

0.5 lt |

||

|

Fresh milk |

1.000 – 30.400 |

0.5 lt |

||

|

Vinegar |

1.000 - 22.000 |

1 lt |

||

|

Juice |

1.000 - 40.500 |

0.5 lt |

||

|

Soy sauce |

1.000 - 36.800 |

0. 33 lt |

OTHER DATA

|

Bottles capacity |

0.2 lt ÷ 12 lt (HC) |

|

|

Production speed |

1.000 ÷ 48.000 bph |

|

|

Filling valves |

9 ÷ 60 |

|

|

Workable caps |

Plastic screw cap, press on cap |

|

|

Workable bottle diameter |

44 ÷125 mm (215 mm versione HC) |

|

|

Workable bottle height |

160 ÷ 340 mm |

|

|

Bottle handling |

Neck Handling |

|

|

Operator panel |

Touch screen 7" |

220 otros productos en la misma categoría:

- Nuevo

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

TPM 1000 fully automatic thermoforming packaging machine

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Filling and seaming groups for aluminium and tin plate cans

- Nuevo

- Nuevo

- Nuevo

GF series automatic plastic bottle filling and capping production line

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuevo

- Nuevo

Vertical form-fill and seal machine of the “Economy” series

- Nuevo

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

AUTOFLOW Automatic Bag in Box and Stand Up Pouch Filler

- Nuevo

DABL series automatic aseptic plastic bottle filling and capping machine

- Nuevo

- Nuevo

- Nuevo

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT