- Nuevo

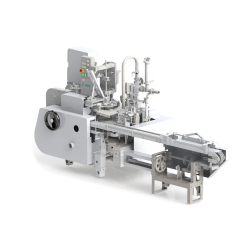

Semiautomatic filling machines

Our semiautomatic filling machines are characterized by their precision, reliability, versatility and ease of use.

Descripción

The filling is entrusted to volumetric piston fillers entirely made of AISI316 stainless steel. This allows us to accurately dose liquid and dense products, even hot and with suspended pieces, into plastic and glass bottles or jars in the food, cosmetic, chemical and para-pharmaceutical industries.

Our piston fillers can fill from 1ml to 5600ml, according to the model chosen. The filling volume can be manually adjusted from the appropriate handwheel, depending on the product and customer’s format.

Our dosers work with 6bar compressed air, are actuated by stepping on the pedal and have simple and intuitive controls. Thanks to the clamp fittings, all the components can be easily disassembled and cleaned without the use of special tools.

Why choose a Telm filling machine?

Reliable and precise

The piston filler precisely delivers the quantity of product set by the appropriate handwheel. Every time the operator steps on the pedal, the filling machine delivers in a regular and steady way the volume previously chosen.

Depending on the type of the product, we will recommend you the most suitable valve to dose it accurately.

Simple and intuitive

Our volumetric fillers are designed to offer customers the maximum ease of use.

Through the handwheel it is possible to choose the volume to be filled, within a range defined according to the model chosen.

Furthermore, by acting on the suction and dosing speed regulators, you can treat products of different viscosities, from liquid to dense, with the same machine.

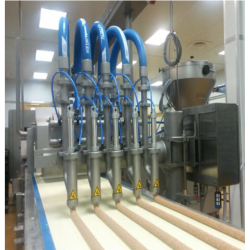

Customizable and modular

Depending on the viscosity and type of product, our semi-automatic filling machines can be modulated and customized with:

• filling valves for thick products, even with pieces (sauces, ragout, jams, pâtés, creams, yogurt, ricotta, burrata, mayonnaise, ketchup, etc.)

• filling anti-drip valves for liquid and filamentary products (fruit juices, liquids, tonics, liquors, oil and vinegar, perfumes, essential oils, disinfectants, pesticides, detergents, solvents, honey, glucose, vinyl glue, acrygel, etc.)

• standard dispensing nozzles or with anti-drip system, anti-foam and wire cutter.

• hoppers of various sizes and customizable with heating and/or mixing systems

• ad hoc structures designed to meet specific customer needs (ground structures, mobile trolleys, supports for baking trays, etc.)

Quality of the materials used

All our machines are made of AISI316 stainless steel and with commercial pneumatic components of Italian origin. This allows us to maintain high standards in terms of quality and performance of our machines.

220 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

TPM 1000 fully automatic thermoforming packaging machine

- Nuevo

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

DABL series automatic aseptic plastic bottle filling and capping machine

- Nuevo

- Nuevo

GF series automatic plastic bottle filling and capping production line

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

AUTOFLOW Automatic Bag in Box and Stand Up Pouch Filler

- Nuevo

- Nuevo

- Nuevo

- Nuevo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuevo

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Filling and seaming groups for aluminium and tin plate cans

- Nuevo

- Nuevo

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Vertical form-fill and seal machine of the “Economy” series

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT