- Novo

Bulk weighing system

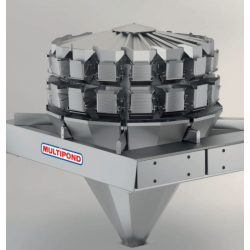

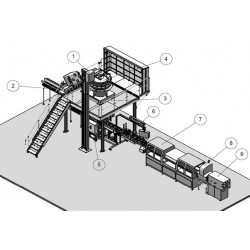

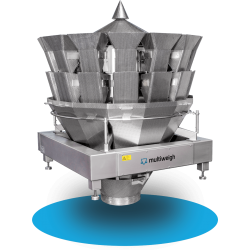

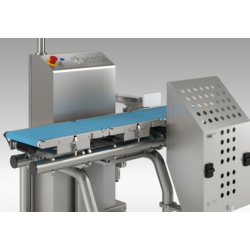

The W SERIES bulk weighers for receiving and shipping bulk material are recognised for their accuracy, performance and reliability.

Descrição

Main benefits

- Performance

- High-capacity, dust-tight and up to 10 tonnes capacity.

- Reliability

- Electronically controlled weighers designed for consistently receiving and shipping free-flowing bulk materials.

- Design quality

- Robust design, manufactured in welded stell for reliable constant operation.

The W SERIES bulk weighers for receiving and shipping bulk material are recognised for their accuracy, performance and reliability. These electronically controlled weighers designed for receiving and shipping free-flowing bulk materials are typically used in grain silos, the feed / food industries, mills, warehouses etc.

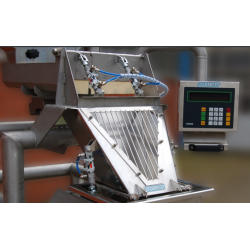

The weigher output is dependent on the size of the weigh hopper, which can be up to 10 tonnes capacity. The weighers are manufactured in welded steel and are dust-tight. Infeed and weigh hopper are equipped with pneumatically operated (twin) gates. The weigh hopper has an inspection door and frame on which to place calibration weights.

Up to 1,520 tonnes per hour depending on type and hopper size.

Features

- Pure full load cell systems reduces maintenance costs

- Fulfils today’s weighing systems requirements for accuracy, performance and reliability

- Removable doors permit easy access and simple clean-down

- Robust design for reliable constant operation

- In-house manufactured BULK weigher control to suit different applications

Options - Level indicator

- Pneumatic anti-freeze

- Calibration weights positioned by pneumatic cylinders

- Duplex in feed

- Stainless steel contact parts

- Abrasion resistant steel contact parts

75 outros produtos na mesma categoria:

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT