- Novo

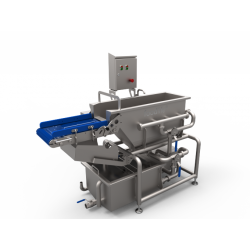

Automatic inline bottle cleaner model BR15

Contract price

ACASI Automatic inline bottle cleaner- Model BR 15 machine (conveyor or options included)

Referência:

Automatic inline bottle cleaner model BR15

UPC:

EAN13:

Novo produto

Descrição

Construction features:

- 304 Stainless steel heavy duty stainless steel welded frame.

- Up to 16 cleaning nozzles.

- All contact parts are stainless steel, sanitary, Teflon, Viton and hoses per your requirements.

- Special seals or hoses by order.

- Calibrated guide for fast height changeovers.

Control panel features:

- Omron PLC for all machine logic functions, special modifications on programs available for special adaptations.

- 6in Omron HMI for all machine functions and delays.

- Frequency control drive conveyor speed, acceleration and deceleration.

- Pump pressure, cleaning and drying time controlled on HMI.

- Front panel Start and Emergency STOP for easy access.

- Fiber optic sensors by Omron standard for container gating.

- No bottle no cycle PLC controlled.

Cleaning options:

- Dry: Air ionizing and suction.

- Wet: Water or product cleaning with wet nozzle. Pressure control as well as drying time all controlled in HMI.

Standard features:

- Individual bottle hold for reliable operation.

- Container height adjustment from 1½ to 12 inches high.

- Bottle turning via heavy duty pneumatic rotary actuator.

- Entry and exit bottle gating cylinders adjustable, sideways, up and down and inside and outside.

- Will work with plastic or glass containers.

- No change parts needed for various types of containers.

- Air filter-regulator and safety lockout valve included.

- Spacing and additional bottle control obtained by flow controls mounted on air gating cylinders.

Tank pump options:

- Electric heater with temperature control on HMI.

- Double wall insulated tank.

Electric and pneumatic requirements:

- Standard - 220V, 50Hz or 60Hz, 10 Amps

- 20 CFM @ 80 p.s.i.

118 outros produtos na mesma categoria:

- Novo

Continuous washing machine knives holder

- Novo

Pallet Box and Stacking Container Washer CLT PB

- Novo

Bottle washer Innoclean SE

- Novo

- Novo

Washing machine with agitating action L4

- Novo

Washers, Cleaners & cip systems

INDUSTRIAL PASS THROUGH WASHER FOR CRATES, UP TO 100 PCS/H

Contract price

- Novo

Washers, Cleaners & cip systems

Perfectly clean vegetable crates thanks to unique Pivo system

Contract price

Perfectly clean vegetable crates thanks to unique Pivo system

- Novo

- Novo

Washers, Cleaners & cip systems

INDUSTRIAL WASHER FOR 200 L BUGGY WITH STANDARD FILTER

Contract price

- Novo

Sink unit cabinet Type SPS-2B

- Novo

Brüel Systems flume washer

- Novo

Cabin washing system Type HWA-Highline

- Novo

Installation for washing plastic meat crates.

- Novo

Vegetable Washing Machine CD1000

- Novo

Orbit Bottle Cleaner/Rinser

- Novo

Brüel Systems tunnel washer

- Novo

LQ-BS Automatic Bottle-inverter Sterilizer

- Novo

Tray Washing Machine, Crate Washing Machine

- Novo

Knife Disinfection Basin MB-S

- Novo

U-shaped washing unit with rotate and tilt function

- Novo

Monoblock automatic cleaning unit

- Novo

CIP Manual Mobile System

- Novo

Bin washers Cabin Design

- Novo

Centralized CBU chemical units

- Novo

Buggy / meat truck washer TC-2000-CC

- Novo

Washing System model Optima L20

- Novo

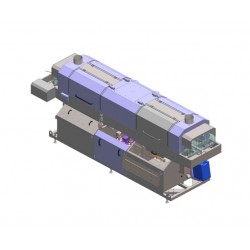

Washers, Cleaners & cip systems

Industrial washing-machine & forced air drying module

Contract price

- Novo

Washers, Cleaners & cip systems

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

Contract price

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Novo

Foam generatos 2 Products online

- Novo

SVSS Steam-Vacuum-Sanitizer-Systems

- Novo

Tank cleaning system Risto - Wash 2013

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT