- Novo

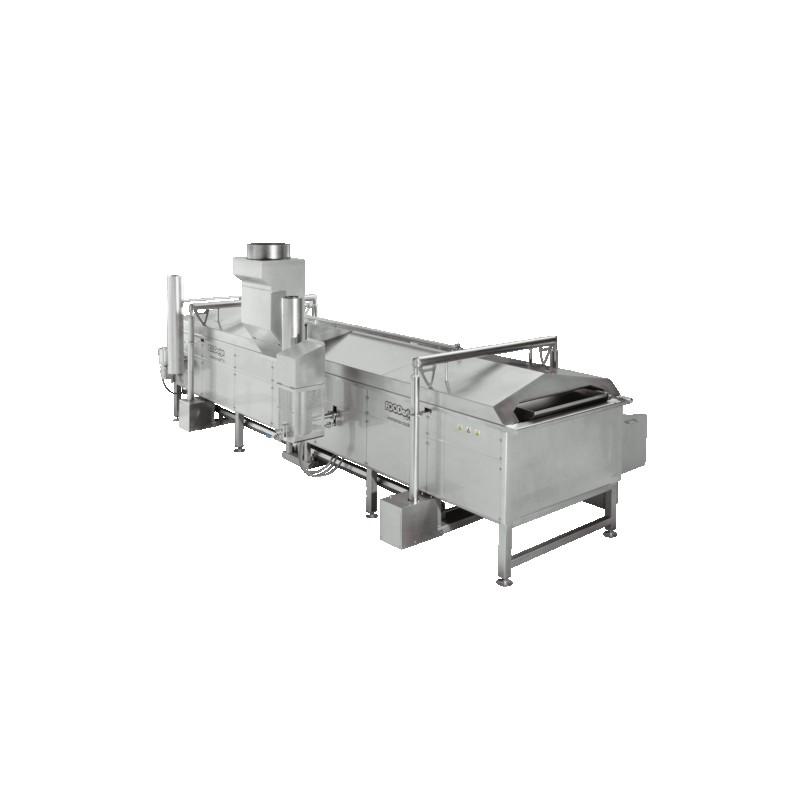

FOODesign immerso-cook® NUT 16

The FOODesign immerso-cook® NUT 16 is a continuous nut roasting system

Descrição

designed for processing almonds, cashews, pepitas seeds, sunflower kernels, peanuts, amongst other nut- and seed-based products. Delivering 80% energy efficiency via serpentine stainless-steal heating tubes, the system saves up to 20% on gas costs and maintains consistent oil temperatures. The continuous roaster also features an internal, direct-heated system and continuous oil filtration, for evenly roasted nut and seed products.

Benefits

Achieve consistent and even seed and nut roasting for capacities up to 4,500 kg/hr (9,900 lbs/hr) with unique mirror-finished serpentine stainless-steel heating tubes

Enhance outputs using a combustion skid with a high flow blower that offers up to 80% energy efficiency

Boost profits by increasing oil life with a sediment removal system through which a waste augur continuously removes sediment and an oil filtration process removes fine particles as small as 500 μm

Reduce total cost of ownership with a durable stainless-steel construction that meets the highest safety standards for a long lifecycle

Surpass operational efficiencies with quick cleaning using a motorised steam hood lifting system, integrated CIP nozzles and open design around the heating tubes

Promote sustainability by saving on energy and natural gas; efficient heating reduces energy consumption and the steam demister creates a cleaner environment

standard features

Infeed vibratory motion conveyor with hopper

Roaster infeed hopper to manually adjust product bed depth during production

Pre-mixed modulating heating technology

Mirror-finished serpentine stainless-steel heating tubes

Roaster conveyor with side guide to prevent product damage

Sediment removal system with waste auger

Motorised, steam hood lifting system with synchronised mechanical drive and integrated CIP nozzles

Heavy duty construction

Direct-heated system

Hot oil pump

Combustion skid

Continuous oil filtration via drum filter

Partial oil filtration via paper filter

Cooling conveyor

Night oil tank with transfer pump set

Controls system

optional features

Steam de-mister

Fire suppression system

Fresh oil tank with transfer pump set

Cooling conveyor integrated with FOODesign quik-coat® RD 5 and tna quik-coat® MLS 3

tna intelli-flav® MLS 3

tna intelli-flav® OMS 5.1

specifications

FOODesign immerso-cook® NUT 16

model NR-500 NR-1000 NR-1500 NR-2000 NR-3000 NR-4500

roaster output capacity kg/hr (lbs/hr)* 500 (1100) 1000 (2200) 1500 (3300) 2000 (4400) 3000 (6600) 4500 (9900)

heater maximum power kW (MBTUH) 108 (0.37) 249 (0.85) 352 (1.1) 498 (1.7) 747 (2.55) 996 (4.25)

heater tube Ø 75 (3)

system dimensions with infeed vibratory motion and cooling seasoning conveyor length mm (in) 8173 (322) 10611 (418) 11831 (466) 14269 (562) 17037 (670)

width mm (in) 2110 (83) 2516 (99) 2716 (107)

conveyor width mm (in) 600 (24) 1000 (40) 1500 (60)

electrical power KVA 38.2 39.8 43 44.6 51 52.6

paper filter optional

model FBP-45 FBP-80

length mm (in) 2150 (85) 3200 (126)

width mm (in) 900 (35) 1435 (57)

height mm (in) 1575 (62) 1415 (56)

oil flow max. m³/hr (cfm) 4.5 (2.65) 8 (4.71)

filter micron (mm) 37 / 120 (0.037 / 0.12)

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT