- Novo

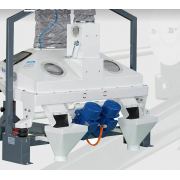

Destoner

The SCHULE destoners ST and ST D are used for the separation of stones in a continuous process.

Descrição

Due to its mode of operation, the destoner separates specifically heavier components from the lighter accepted product. Stones, broken glass and metal can be sorted out with a high degree of separation, even if they do not differ from the accepted product in size and shape.

It consists of an inclined screen box mounted on hollow rubber springs with a feed flap that distributes the contaminated product uniformly over the working surface of the machine. The working surface is provided with an optimum air flow by its own fan. By an oscillating movement of the destoner in combination with the working surface, through which air flows uniformly, a precise separation of light and heavy particles is ensured.

Stones and other specifically heavier particles sink to the working surface and are discharged via a separate outlet by the diagonally upward conveying movement, while the suspended accepted product flows through gravity to the lower outlet.

The SCHULE destoner is available in two types and three different sizes. It is equipped either with one working surface as described above or with two one on top of the other. Due to this diversity, a wide capacity range and a high product variety can be covered even with strongly contaminated products. The various applications range from oats, wheat and rye to barley, buckwheat, millet and quinoa.

Due to the gentle working method, the product and the machine are only subjected to minimal stress, which has a positive effect on the subsequent yield and wear of the machine.

Advantages of the destoner:

Easy to operate and maintain

Variable application possibilities

Wide capacity range

High separation accuracy

The SCHULE dry stoner is one of many high-performance cleaning machines made by Schule. Its application not only greatly improves the cleaning process, but also ensures the operational reliability of subsequent machines in this process, such as the indented cylinder.

Please feel free to contact us if you have any questions.

Just write a message using our contact form.

20 outros produtos na mesma categoria:

- Novo

- Novo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT