- Neuf

Compact, automatic traysealers

Compact design. Maximum output. Minimum consumption of resources.

Description

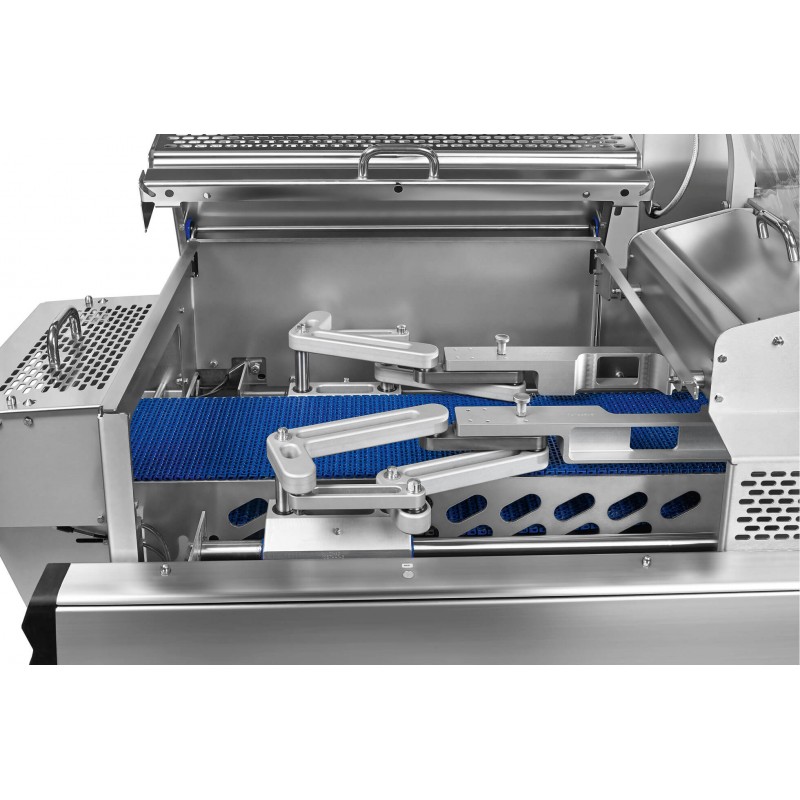

Our compact automatic traysealers are the smart choice for packaging applications in the medium-output range. These models, which are constructed in the MULTIVAC Hygienic Design, are suitable for producing attractive MAP and vacuum skin packs of a consistently high quality, and they are characterised by their gentle tray handling and high level of efficiency - even at maximum output.

As a leading manufacturer of automatic traysealers, we focus primarily on our customers. Each machine is designed individually to the customer's specific requirements as regards the product and tray, and this means that every traysealer fits seamlessly into new or existing production environments.

MULTIVAC traysealers are characterised by maximum output at minimum use of resources, and they also provide optimum utilisation of the available production space. They are efficient, flexible, durable and particularly cost-effective as regards investment and operating costs. Together with state-of-the-art die change systems, their ergonomic design ensures that they can be converted easily and quickly to other pack formats - and this reduces downtime to a minimum. All the models can be easily integrated into automated lines, and their small footprint has a particularly positive impact.

The compact automatic traysealers from MULTIVAC are ideal for producing attractive MAP and vacuum skin packs of a consistently high quality. There are hardly any limits to pack shape or materials, since they can run a wide range of trays made from plastic, aluminium, cardboard and foamed materials, as well as a broad spectrum of upper webs including register printed films. A wide range of opening aids can also be integrated into the pack.

The various models differ primarily in terms of format size and available equipment options. As with every MULTIVAC packaging solution, they guarantee very simple operation and the highest level of efficiency.

Benefits at a glance

Simple and safe operation

IPC control with HMI 2.0 graphic user interface

Support from the machine control for set-up processes

Wide range of equipment options for maximum operating safety and ergonomics

MULTIVAC Hygienic Design™

Customised configuration

Capable of running a wide spectrum of packaging materials such as plastic, aluminium, foamed and fibre-based materials

MAP and MultiFresh™ vacuum skin packs can be produced

Wide range of equipment options for sealing and cutting systems

Capable of integrating many different types of loading, labelling, monitoring and converging systems

Can be equipped with the MULTIVAC Tray Carrier system (MTC) for trays, which can not be run on standard systems due to their shape, size or centre of gravity

Cost-effectiveness and efficiency

Efficient use of energy and packaging materials

Very high production output and pack quality

Wide range of equipment options designed to reduce downtime

Robust and durable stainless steel construction

Capable of modular extension as well as retrofits for new functions and applications

448 autres produits dans la même catégorie :

- Neuf

Machine for the production of thermoshrinking bags SA-V TVB

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

TPM 1000 fully automatic thermoforming packaging machine

- Neuf

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

- Neuf

- Neuf

- Neuf

Vertical form-fill and seal machine of the “Economy” series

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

GF series automatic plastic bottle filling and capping production line

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- Neuf

MC4TB High-speed wrapper for chocolate tablets and bars

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Filling and seaming groups for aluminium and tin plate cans

- Neuf

Seamer for soft drinks, beer and carbonated soft drinks

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

LRC-700 Combined Robotic Case Packer & Palletizing System

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT