- Neuf

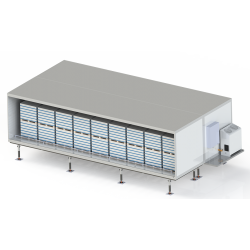

AIRMASTER® IKK

The AIRMASTER® IKK series units are intensive cooling systems for fast, safe and economic cooling of cooked products.

Description

The shelf life and quality of the products are considerably increased as a result of the fast passage through critical temperature ranges. AIRMASTER® IKK units have the same high-quality housing as the units of the UK series and are just as impressive with their uncompromising quality – 100 % Made in Germany.

Maximum cooling performance and efficiency

Energy efficiency through intelligent processes

Maximum yield and shelf life

Best product quality and microbiology

Optionally with boil function

High load capacity

Tightly welded chamber modules

Fully stainless steel 1.4301

Mineral full insulation

No uninsulated housing parts

Small width and height

Low-maintenance and reliable

Particular stability and service life

Made in Germany

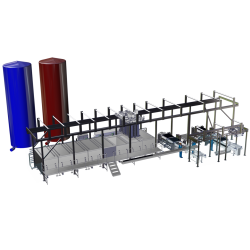

The AIRMASTER® IKK series units are intensive cooling systems for fast, safe and economic cooling of cooked products. The shelf life and quality of the products are considerably increased as a result of the fast passage through critical temperature ranges. The optional cook function makes the unit even more versatile in turns of possible uses. AIRMASTER® IKK units work with vertical airflow and are perfect for hanging products and are also suitable for lying products with the loading capacity adapted. IKK intensive cooling systems can be supplied in all desired sizes from 1 to 14 trolleys in single or double-row versions.

The areas of application of the AIRMASTER® IKK have been matched to the varied requirements. Whether cooking, rinse cooling, intensive cooling, drying or evacuating. With the AIRMASTER® IKK, you get an all-rounder for your production.

After evacuating the cooking steam, the product is first pre-cooled in a cool rinsing procedure (optional with ECO Boost fine atomisation). The intensive cooling phase then follows, in which the product is cooled to the desired core temperature of 5-10° C by activated cooling batteries. The controls can use different intelligent cooling methods here so that the products are treated as gently and energy-efficiently as possible. The goods can be packed immediately after the cooling process.

Naturally there is integrated, fully-automatic CIP cleaning. Many available equipment options ensure that you can configure your unit precisely according to your specific requirements.

The cooling system is always adapted to the cooling medium used in the respective mode.

Unit Description

The design of the AIRMASTER® IKK units is based on a modular kit system. Components such as controls and cleaning system can be arranged individually according to your desires or spatial requirements.

Depending on the unit size, the chamber housing of AIRMASTER® IKK comprises one or more chamber modules. Each chamber module is very sturdy and is made of 100 % chromium-nickel steel, material no. 1.4301, and is welded to be gas and steam-tight. Mineral full insulation (temperature-resistant up to +650°C) protects against heat losses. Importance was attached to avoiding thermal bridges in the construction of the unit.

The top section and the side walls of each chamber module contain the air preparation unit with ventilator and intensive cooling package. The greatest advantage of this modular system compared to systems with a central unit is that each chamber trolley is supplied exactly the same with air and cold energy and therefore absolute consistency is also ensured from trolley to trolley.

Added-value from modular design:

Same results in all trolleys

Tightly welded chamber modules

Fully stainless steel 1.4301

Mineral full insulation

No uninsulated housing parts

Small width and height

Low-maintenance and reliable

Particular stability and service life

The AIRMASTER® IKK works with the proven vertical airflow principle. Highly efficient ribbed pipe cooling batteries made of stainless steel are integrated in the sides of the unit. The cooling battery's effectiveness is increased to the maximum with the special air guide.

More output:

Maximum cooling performance and efficiency

Energy efficiency through intelligent processes

Maximum yield and shelf life

Best product quality and microbiology

High load capacity

Only high quality products from German brand manufacturers are used for all heavily used parts such as motors, ventilator impellers, valves, cylinders, etc. In this way we ensure that the highest quality and reliability are achieved in detail.

Each AIRMASTER® has a robust chamber floor. Packing with heavily loaded chamber trolleys is not a problem. In a special version, packing is also possible using forklifts. The floor construction is kept very flat and has a sloped entrance. The substructure of the chamber floor is reinforced in the direction of travel with strong U profiles.

All AIRMASTER® systems are fitted with one or more fully insulated, stable block doors, which are sealed against the chamber housing all the way around with a silicon seal. The door hinges are made entirely from chromium-nickel steel for the high demands of seal and long service life. The door stop can be fitted left or right as required.

For fresh air, exhaust and smoke flaps, tight-closing, metallic folding flaps or silicon rubber rotating flaps are used. These flaps have multifunctional positions for controlling the amount of the volume flows.

The units can be operated with all standard cooling media (direct evaporation, glycol brine, ammonia).

The AIRMASTER® IKK can be optionally equipped with a cooking function for connection to an on-site low pressure steam supply.

73 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT