- Neuf

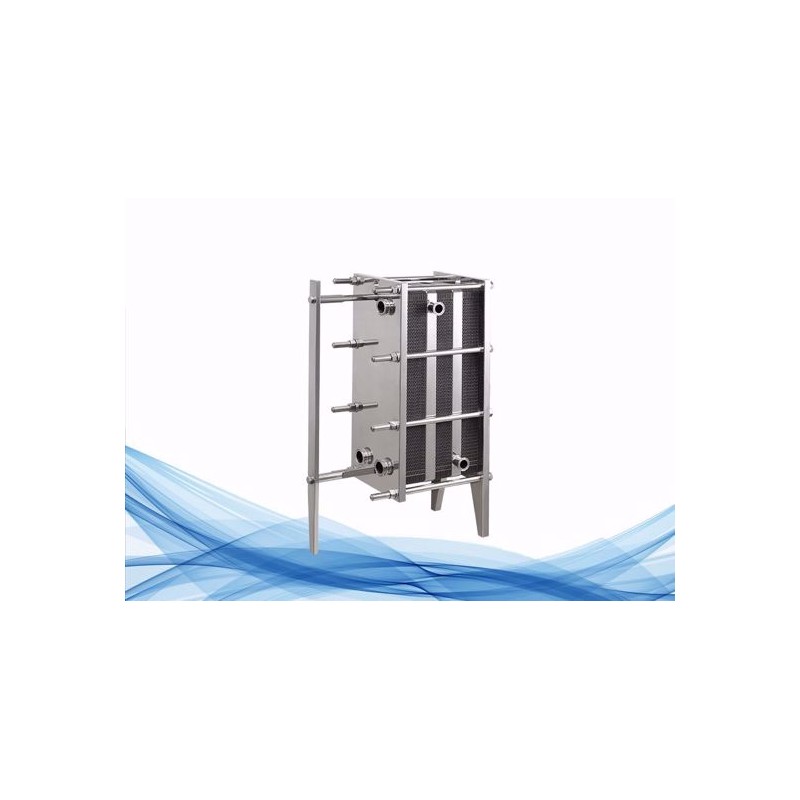

Plate Heat Exchangers

Plate Heat Exchangers have become an effective modern method of cooling or heating flowing liquids.

Description

Product Description

Plate Heat Exchangers have become an effective modern method of cooling or heating flowing liquids through the method of conduction. The application of the Plate Heat Exchangers is basically cooling the hotter liquid or heating the cooler liquid.

The heat transfer plates are thin sheets having corrugations and patterns which increase the surface area of the plate thereby increasing the efficiency of heat transfer through conduction. The liquid is prevented from flowing sideways by thick gaskets which seals the PHE and also directs the liquid to flow in the appropriate alternate channel. The plates are supported and aligned by the guide bars and tightened by bolts between stationary and pressure frame. The equipment can adjust the number of plates to meet the heat duty.

The flow of Fluid and Heat Exchange Mechanism

Heat Transfer plates L and R are of identical pattern. L when rotated 180 degrees become R and vice versa. The plates are arranged in LRLR or RLRL combination giving the PHE a honeycomb pattern when looked from sideways.

The first plate - E plate is having all portholes covered with the gaskets as this plate is touching the stationary frame. This double seal gasket prevents the flow between the stationary frame and the first plate.

Plate Press Patterns

The herringbone pattern is adopted for the plate press because of its high heat transfer efficiency. Combining these plates together creates more contact points making it possible to obtain strong pressure resistance.

In this way, a complex channel is formed creating highly turbulent flows to obtain excellent heat transfer performance.

TYPES OF PHES -

INDUSTRIAL -

Used In Heating / Cooling / Heat Recovery Of Process Fluids For The Following Applications -

Hydraulic Industry - Cooling Hydraulic Oils Used With Hydraulic Power Packs Lubrication Industry - Cooling Lubrication Oil Pharmaceutical Industry - Hot Water Generation Using Steam Induction Furnaces - Process Water Cooling Wire Drawing Plants - Cooling Di Water Rf Heaters - Cooling Di Water Quenching Furnaces - Cooling Quench Oil

FOOD GRADE -

Used In Heating/cooling -

Milk, yogurt, Cream, dairy, Juice, Sugar Syrup Cooling, Juice, And Beverage Cooling, Drinking Water Chilling, Ice Cream Mix Chillers

INDUSTRIES SERVED -

FOOD - DAIRY AND BEVERAGE, STEEL MILLS, TEXTILE, HVAC, HYDRAULIC, LUBRICATION, MARINE, CHEMICAL

MAINTENANCE

It is important to perform maintenance to improve the life cycle of Plate Heat Exchangers

4 autres produits dans la même catégorie :

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT