- Neuf

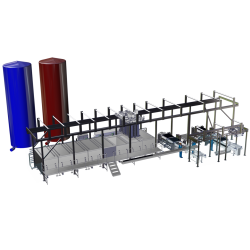

ROTARY DRUM COOKER COOLER INCREASES ROI

Combination blancher/cooker-coolers were first designed in 1995 for blanching and cooling pasta, rice and vegetables.

Description

Combination blancher/cooker-coolers were first designed in 1995 for blanching and cooling pasta, rice and vegetables. The basic process differences between a blancher, cooker or pasteurizer are retention times and operating temperatures. Lyco Cooker-Coolers have the option of doors in the cylinders and clean-in-place manifolds in the cover, the open center flights, and the tank sides. Our combination cooker/coolers have lower maintenance costs and take up much less room than two separate machines and a conveyor in between. The single CIP System cleans both hot and cold zones. Save major floor space with this design.

HOW IT WORKS

Product is fed into the machine by a chute or water cushioned in-feed flume. The cook zone blanches, cooks or re-hydrates, very gently agitating product as it passes through the machine. Product then transfers to the cool zone and gently discharges from the machine. Lyco’s Hydro-Flow agitation guarantees a uniform and thorough process, contributing to a consistent, quality product.

BENEFITS

- Agitation increases capacity by up to 50 percent and reduces losses from pasta clumping by 10 percent

- Lower equipment maintenance costs due to quality materials and fabrication

FEATURES

- Trunnion designs eliminate shaft breakage

- Cylinder designs result in zero leakage

108 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT