- Neuf

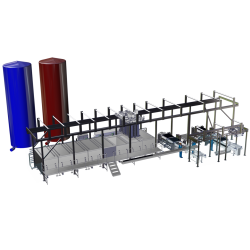

Continuous Screw Cooker COOK C PROFI

The cooker is designed for high productivity and works in continuous mode. It is designed for heat treatment of products at atmospheric pressure, with minimal heat consumption and maximum preservation of nutrients and vitamins.

Description

The continuous cooker saves a lot of time. From an economic point of view, the biggest advantage of the device is that it works in a continuous mode, so you do not waste time filling the cooker with product and then selecting the product again, as is the case with batch cookers.

Ideal for products like:

- seaweed, marine plants

- leafy vegetables, cabbage, spinach

- meat, fish

- mushrooms, etc.

The continuous steam cooker is equipped with a duplicator for heating with steam or hot water, as well as a system of direct steam injection into the product, which is the most efficient way of heating.

The product is evenly fed into the cooking chamber by means of a feeding conveyor and is moved by means of a screw in the direction of unloading. For the greatest efficiency of heat treatment, the principle of intensive hydrodynamic mixing is used in the device, in which the product is moved along the cooking chamber, it also rotates intensively in the transverse plane. Intensive water circulation and direct steam injection ensures even heating and maximum heat exchange, also guarantees that the product does not stick and is heat treated in all the same way.

The speed of the auger movement depends on the required heat treatment time and can vary within certain limits due to the rapid change to a new type of product. The construction of the continuous cooker and has a stable integral frame, which guarantees the safety and durability of the construction even with larger dimensions of the device. Reinforced thermal insulation minimizes heat loss and reliably protects operators from burns to the exterior walls of the equipment.

Product cleaning

Another great advantage of the cooker is that it is equipped with a dirt trapping system. During cooking, impurities from the product fall into a special tank. When the tank is full, the valve opens and the dirt is drained.

Technical features:

- Sanitary shower heads that are connected to an external CIP station

- Drain system with dirt trap

- Product residue discharge system

- Multi-part opening cover - separate opening covers

- Heating: steam + hot water

- Water recirculation circuit

- Water level sensor

- Water filling system in loading and unloading zones

108 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT