- Nuevo

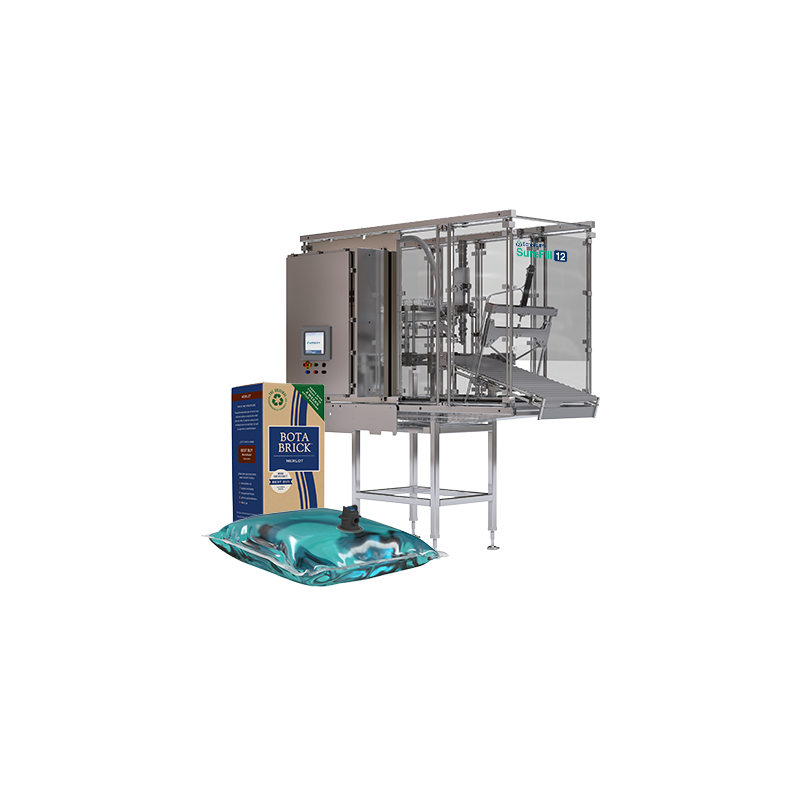

SureFill 12 – Fresh

Advanced bag-in-box filling technologies that delivers versatility and speed.

Descripción

Advanced bag-in-box filling technologies that delivers versatility and speed.

- Ambient-fill capable

- Automatic, web-fed filler

- Fills packages up to 22L

Product Specifications

Key Features

The Scholle IPN SureFill® 12 Fresh is a single-lane, automatic web filling machine. The machine is capable of packaging ambient products in 2- to 22-liter bag sizes. The filler is equipped with a monitor interface to a programmable controller assuring process conditions. All product contact surfaces are constructed out of 316L stainless steel and food grade construction. This system has visual warning indicators; a messaging system that displays fault condition(s) and, if necessary, stops the filling operation. In addition, if necessary, product may be automatically diverted away from the filler with messaging to upstream processing control. This filler is of modular design and can be configured to address a variety of packaging and bag loading options: from flat drop to end loading configurations.

Known Process Applications

Clean Fill (Ambient)

Occurs when a product is filled into a package with no additional sterilization treatment.

Filling Method

Through Spout

Common Package Sizes

2 liters to 22 liters (.26 gallons to 5.8 gallons)

Typical Markets

- Agricultural Chemicals

- Alcoholic Beverages

- Automotive Fluids

- Cleaning Chemicals

- Coffee & Tea

- Dairy

- Edible Oil

- Fruit & Vegetables

- Functional Drinks

- Juice

- Soft Drinks

- Water

Maintenance

Clean-in-place (CIP) machine cycles are applicable. CIP cycle controlled by filler programming, works in line with your existing CIP system to complete CIP circuit. This is a customer-dependent processes and can be initiated from the CIP screen. Our expert equipment field service technicians can support and maintain this filler for your continued success.

Equipment Specifications

Filling stations: 1

Machine dimensions (L x W x H): 2615mm x 1603mm x 2534mm (103in x 63in x 100in)

Air Consumption: 90-140 PSI, 12CFM (dry/oil free)

Electrical Data: 240VAC, 15Amps, 50-60 Hz

PLC: Allen Bradley and Panelview - Series

64 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

TPM 1000 fully automatic thermoforming packaging machine

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT