- Nuevo

AUTOTHERM STEAM SMOKE CHAMBERS

The steam-smoking method further developed by AUTOTHERM is especially suitable for effective production of hot-smoked products.

Descripción

The transfer of smoke by means of condensation on the products to be treated achieves fast and uniform smoking with incomparably low weight losses.

The smoke colour of the products treated with STEAM-SMOKE is extremely colour stable and cannot be washed off either with water or with steam.

The steam and smoke mixture is soot-free and carcinogenic benzo(a)pyrene is hardly detectable.

The lower weight loss compared to traditional smoking methods makes this process extremely economical and the payback period extremely short. These advantages have also been confirmed by independent institutes.

The short smoking times enable a steam smoke generator to be connected to up to three smoking units (with max.4 trolley); this cuts the investment costs. The microprocessors controls the smoke supply to the three units fully automatically. All units are available with waste gas cleaning systems (catalytic afterburner, filtersystem or condenser).

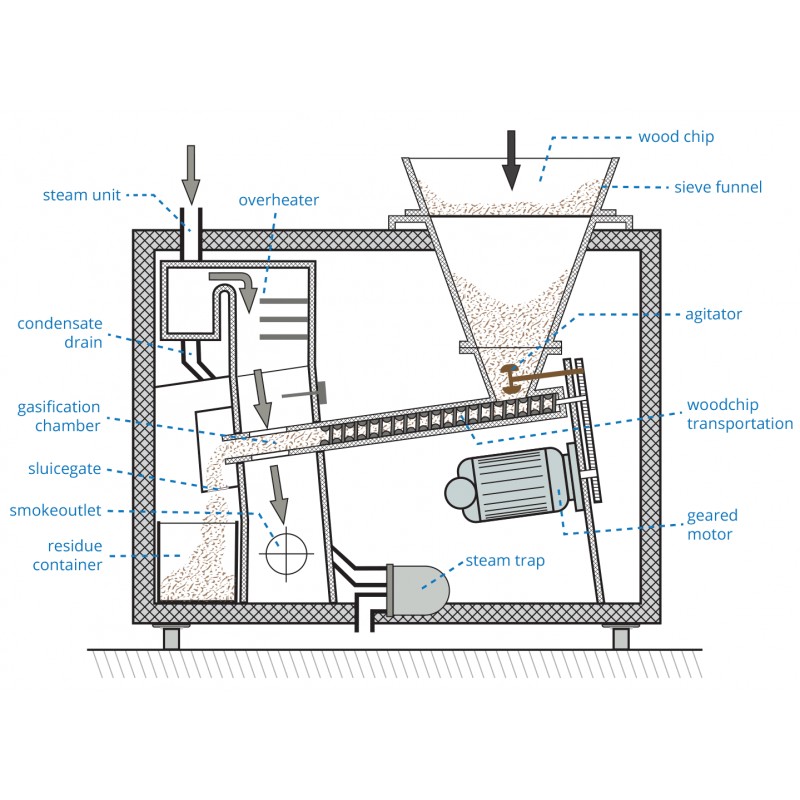

The steam-smoke generator principle

Dampfrauchprinzip_englisch

The steam-smoke generator principle

Steamsmoke is procuced by means of superheated steam, which penetrates the wood chips. All color and flavoring ingredients of the chips are extracted and conducted into the chamber as steam smoke.

Steam-smoke:

- fast

- color proof

- minimal weight loss

- accurate regulation

AUTOTHERM customers worldwide value the advantages of the steam smoke system.

Due to the extremely short smoking times

of the AUTOTHERM steam-smoke process and the

natural moisture, the steam-smoke reduces smoking

times by up to 40% and weight losses by up to 3% compared

to conventional smoke systems.

EXAMPLE:

3 trolleys

AUTOTHERM steam smoke chamber 3 x 200 kg = 600 kg/batch

8 h/day= 4 batches x 600 kg = 2400 kg

with 3% less weight loss, this means: 3% of 2,400kg = 72kg/days x 2.50 €/kg = 180.00 €/day = 3,865.00 €/month = 45.360,00 €/year

APPLICATIONS

cooked or boiled sausages

Hot-smoked meat and sausage

products such as Frankfurters,

Lyoner, Wiener and Knacker

sausages

Kassler (gammon), cooked ham

PROCESS STEPS:

Reddening

Drying

Smoking

Cooking

SPECIFICATIONS:

Temperature range:

+45°C to +90°C

Relative humidity: up to 99%

Other values possible on request!

Technical information

Unit: Steam-smoke units

Heater: Electric, Steam, Oil/Gas

Humidification: Water/Steam

Voltage: 230/400V 50Hz

Trolley size: 100 x 102 x 198 cm

Trolleys per unit: 1-10

Capacity per trolley: approx. 200 – 250 kg

Type: Stainless steel panels

Control: Microprocessor

Waste gas cleaning: condenser, Catalytic after-burner (gas or electrically heated)

On the customer’s request the units can be equipped with electronic speed control, an additional electric heater for baking up to 150°C, a shower system and automatic door opener.

18 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT