- Neuf

- Neuf

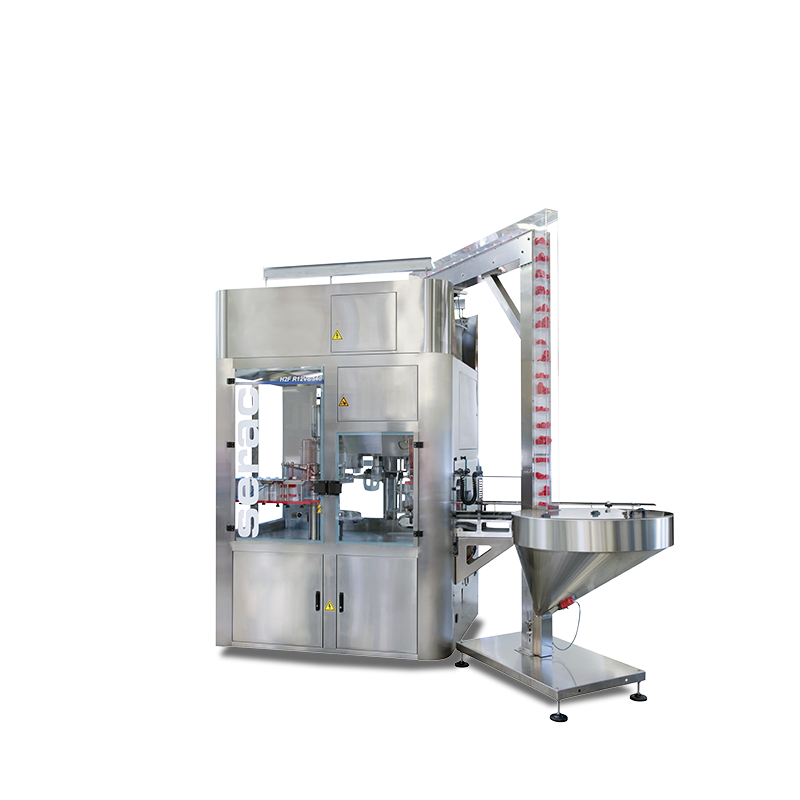

H2F Filling & Capping

The good choice for chilled beverages.

Description

The good choice for chilled beverages.

Filling & Capping

- Modular and upgradable system

- Chemical-free decontamination of caps

- Optimal hygiene preserves food products quality

Outputs: up to 42,000 containers per hour

Containers: bottles

The increase in consumption of take-away beverages has led to the development of the H2F. Thanks to neck transfer technology, this solution is both flexible and helps reduce change of format time, thus increasing productivity.

Advantages

Modular system

The H2F is compact and modular which enables rapid installation. According to your needs, additional modules such as decontamination of container, heat-sealing or neck trimming may be added. This filling machine may be incorporated into a Blowing-Filling-Capping (Combox-H2F) system for customers who wish to produce PET containers on site.

Hygienic design

The machine is designed in accordance with the most recent generation of SAS aseptic filling machines in order to develop a version specifically adapted to the filling of chilled liquid foodstuffs.

Chemical-free decontamination of caps

In-line decontamination of caps using pulsed light enables reduction of the Aspergillus Niger by 3 Log. No chemical products are used, no storage, management of waste, no inconvenience for the operators.

Technical characteristics

Filling

- Weight filling

- Neck transfer

- EHEDG load sensor

- Patented filling tank

- Metal-to-metal seal

- Magnetic valves

- Tank equipped with a rotary coupling and offset nozzles

Capping

- Mechanical screw-capping elements offset from the filling zone

- Central torque setting via the HMI

- Possibility to equip the machine with a heat-sealing station for aluminium foil lids.

Hygiene

- HEPA filtration

- ISO 5 unidirectional airflow

- Air pressurisation

- Cleaning collector

- CIP in closed loop circuit

- Hot water sanitation of the filling circuit

4 410 mm Max. length

1 260 mm Max. width

2 070 mm Max. height

Optional equipment

- Heat-sealer

- Neck trimmer

- Container decontamination module

- PET blower

21 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT