- Neuf

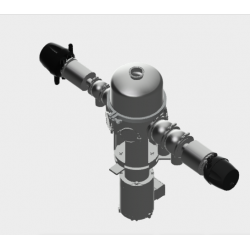

DICON™ Continuous Blenders for Beverage

Contract price

DICON™ in-line blending concept for the beverage industry

Liquid multi-component products in the beverage industry are always subject to increasingly complex demands on efficiency in ever faster innovation cycles. Production systems designed to satisfy those demands need to be economic, reproduce the process exactly, and have the highest possible flexibility. This is exactly what continuous in-line blending with DICON™ technology from GEA offers.

UPC:

EAN13:

Nouveau produit

Description

"Continuous in-line blending" - what does it mean?

- The individual liquid components are mixed directly in the pipeline.

- All components are simultaneously added to the mixing process.

- The mixing ratio of all components is permanently controlled.

- The homogeneously mixed finished product leaves the unit.

- Critical product parameters are subject to an in-line quality analysis.

Different types of DICON™ in-line blending systems

- Continuous in-line blending system DICON-B™

Used in breweries for original wort optimisation (HGB procedure) - Continuous in-line blending system DICON-C™

Used to mix soft drinks - Continuous in-line blending system DICON-S™

Used to mix syrup for soft drinks - Continuous in-line blending system DICON-T™

Mobile (portable) system to mix liquid components - Continuous in-line blending system DICON-Y™

System to mix fruit and yoghurt - Continuous in-line blending system DICON-MS™

Used to standardize cream and milk - Continuous in-line blending system DIVA™

Alcohol reception and blending

184 autres produits dans la même catégorie :

- Neuf

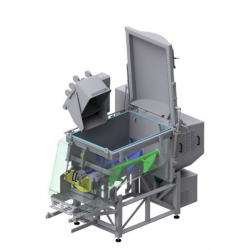

Overturnable Mixer NUOVA VITTORIA

- Neuf

PREMIX FOR WINE AND GRAPE JUICES

- Neuf

DLM/FS Solid-Liquid Inline Mixer

- Neuf

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- Neuf

CHOCOCON 150 chocolate / compound processing unit

- Neuf

Mincer mixer AK-RAMON PM-32 PM-114

- Neuf

Dough-kneader machine МТ-300 K.423

- Neuf

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- Neuf

Vertical Spindle Dough Mixer 550

- Neuf

Coating and Enrobing machines

Continuous drum coating machine for adding spices and flavors AD

Prix

8 900,00 €

- Neuf

MIXWORKING BATCH - PASTEURISING PLANTS

- Neuf

MIC Turbo – Mixer Granulator – Food

- Neuf

Blending system Innopro Paramix C

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT