- Neuf

COCTIO AIOS

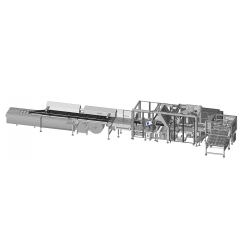

Automated, all in one cooking system for R&D, pilot and industrial production of high-quality natural bone broths and other liquid food products.

Description

Profit-making line with a low initial investment to succeed in highly evolving bone broth market

Compact, all in one Coctio Mobile cooker line is an ideal solution for the efficient and economical processing of protein-rich broth and stock full of delicious flavour. It ensures the high character for natural end-products as it follows proven Coctio cooking principles based on the traditional way of cooking meat and fish bones in water, requiring no additives in the process. A precise process control system ensures consistent product quality.

The ready-built, tested line will be installed in production facility within a couple of days, and you would only need to connect utilities to it, such as steam, electricity, water and data. The system brings time and costs savings, as it can run 24/7 and can cook unsupervised overnight with no operators on-site.

When Coctio mobile line is added to an existing process in a production facility for product testing purposes to develop bone stock recipes and products and to set up a commercial production, or new business start-up is desired from scratch, you're taking advantage of extracting various high-value end products by transforming category 3 bones material into a raw material of considerable high commercial value fit for human consumption. Mobile line is available with a relatively low initial investment allowing a quick return on investment.

Video: Broth cooking process in use

Capacity & Functionalities

Cooker size of 4300 litres, an output of about 2200 litres of stock (1800 kg of bones, 2000 litres of water).

For example maximum yearly production of chicken bone broth => 1,800,000 litres of stock/year, requires about 1,600 tons of bones.

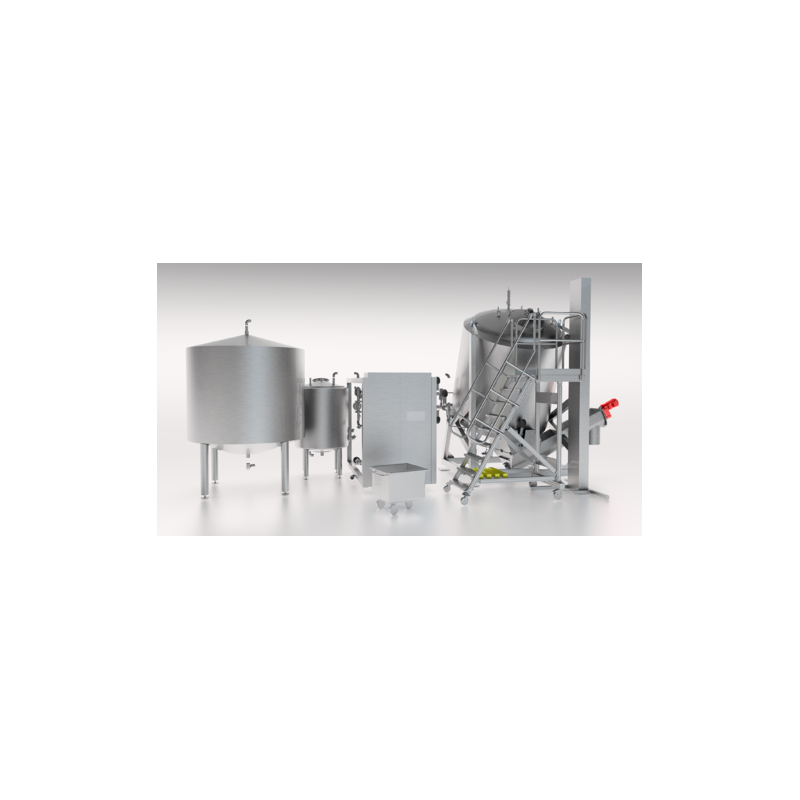

The Mobile cooker line includes the following equipment:

Coctio Mobile Bone Broth Cooker System1. Bone broth cooking

4300-litre closed, tilted, insulated cooking vessel with vertical pillar lift and tip system, and mobile access platform

2. Broth filtration

Broth filtration system

3. Storage

4,5000-litre closed and insulated end-product storage tank with vertical mixing arm attached to the top of the vessel

4. Cleaning

Simple Batch Cleaning-in-Place (CIP) station

97 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

Depilation centrifuge type D40, D45, DM-40-CE, DM45, DM50

- Neuf

- Neuf

- Neuf

Automatic scalding and dehairing machine Type H(N)SKR or H(N)SKL

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT