- Neuf

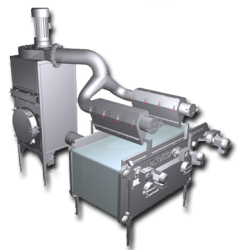

Salami Machine

The VELEC salami machine has been developed for the most demanding customers looking for sanitation and gentle handling of their Hot Dogs.

Description

The VELEC salami machine has been developed for the most demanding customers looking for sanitation and gentle handling of their Hot Dogs. It is an extremely versatile system and an easy to use salami machine.

Sanitation of the VELEC salami machine

The VELEC salami machine is placed right after your salami cooking process, between the salami peeling or cutting unit and its primary packing system. It is absolutely of prime importance to make sure that this area of your process is the most hygienic designed area to prevent the development of bacteria before packing the salami.

Therefore, the VELEC’s engineering team has concentrated all its effort to make the VELEC Salami machine the most hygienic design solution available on the market.

Every single details of our VELEC Salami machine fulfil and overpass the recommendations of the meat Industry and the best practices of the European Hygienic Engineering & Design Group (EHEDG).

As an example, our VELEC Salami machine have the following key characteristics:

• Fully manufacture in stainless steel, any single part of our VELEC Salami machine is glass bead finished to have minimal surface roughness for a very hygienic solution.

• To avoid water retention area, the VELEC Salami machine is designed in a way to avoid any horizontal flat surface and to have only inclined surfaces.

• The VELEC Salami machine is fully welded with very minimal quantity of bolts, nuts and timing screws, areas which are difficult to access and clean.

• Contrary to our competitors, the VELEC Salami machine has absolutely no hollow tubing construction, neither in the structure of the machine, nor on the robotic frame.

• The VELEC Salami machine use only IP69K components from sensors to actuators, fully stainless steel (no aluminum),

• Because modular belts are well known for all the small holes and areas which are impossible to clean, the VELEC Salami machine use exclusively smooth belts.

• Last but not least, the VELEC Salami machine can be fully disassemble without any tools and all the components have a dedicated place once disassembled either on the frame of the machine or on a dedicated trolley.

Gentle Handling of your Hot Dogs to maximize profit ($$$)

Most of the salami machine currently available on the market generate a large quantity of broken salami which is totally un-acceptable for the most important person: the final customer.

Consequently, salami manufacturers are forced to employ people to inspect every single sausage during the packing process and to remove and replace broken salami. This operation does not create value and force the salami manufacturer to reprocess those broken salami. So much money lost!

At VELEC, we have spent a lot of time to make sure that our VELEC salami machine do handle your salami with care. Right from the beginning, the salami are carefully handled by an hygienic smooth belt. Then, the salami are delivered on the cone of the centrifugal machine where it rotates and thanks to the centrifugal force, they slide by their own weight on the periphery to transfer one by one on the drum’s edge. Then the salami are driven one by one behind each other on the exit conveyor, then transferred to the piano belts. Finally, the hygienic design pick and place robot gently picks and smoothly places the salami in their primary package.

The most versatile Salami machine for every packing configuration

Salami manufacturer do rarely manufacture only one type of hot dog but usually deal with a very large range where recipes, diameter, length, weight and casing vary.

The VELEC salami machine can load all types of salami whatever the diameter, length, with or without casing (including cellulose casing).

When it comes to load into the thermoforming machine, the VELEC Salami machine can place salami in all direction, parallel or perpendicular to the film movement.

The HMI of the VELEC Salami machine gives access to the “Recipe” menu, where salami manufacturers will define the number of pockets according to the die of the thermoforming machine, the product orientation, the number of layer per pocket, and the number of sausages per layer.

The VELEC Salami machine will even permit to load uneven number of sausages per layer (ex: 6 + 5).

The VELEC Salami machine: the most user friendly and secured Salami machine on the market

Employees are the most important asset of any organization. Therefore, we have designed the VELEC Salami machine to make their life easy and secured. For that reason, every single element of the machine is on the floor level without any stairs or platform, and operations are reduced to the very strict minimum.

Interactions for the operators are minimal and have been studied for the best ergonomics.

Finally, the VELEC Salami machine’s HMI is as intuitive as your smart phone and will give access to all type of information, including videos showing how to disassemble and clean the line.

33 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT