- Neuf

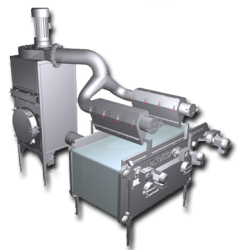

Moba-Coenraadts egg shell centrifuge systems C430-V and C430-RB

Egg shell centrifuges are primarily designed to extract remaining liquid from shells coming from a breaking machine.

Description

Obtaining as much yield as possible from egg processing is vital. However, the shells that are released from the egg breaking machine still contain a small amount of remaining liquid. Collecting this ‘technical albumen’ however is worthwhile for various reasons:

- Technical albumen represents a certain value, even though it is not suitable for human consumption.

- Egg shells need to be pasteurized. This is generally done by heating. In order to reduce the amount of energy required for pasteurizing, shells should be presented as dry as possible.

Also in the grading industry, a certain amount of liquid egg is available from leakers discarded by the egg grader. Liquid from these kinds of eggs can be sold as raw material for non-food applications.

Functioning of the centrifuge

Egg shell centrifuges are primarily designed to extract remaining liquid from shells coming from a breaking machine. Further on, shells are compacted during the process, making them more suitable for transport.

Obviously, there is quite some difference between whole eggs and just shells. Putting whole eggs into a centrifuge, designed for empty shells only, will cause considerable damage to the equipment quickly.

Different eggs require different solutions. Therefore the Moba-Coenraadts eggshell centrifuge comes in 2 different versions:

- C430-V: Specifically designed to process empty shells form an egg breaking plant.

- C430-RB: Engineered to be able to handle whole eggs as well. This centrifuge has a dosing unit mounted on top of the actual centrifuge. The dosing system regulates the amount of whole eggs that can fall into the centrifuge and makes it possible to use the centrifuge in an egg grading environment as well.

Functioning of the centrifuge itself is quite straight forward. Shells or whole eggs are fed from the top. The special extracting auger separates shells and fluids in the best way possible. The surrounding construction leads shells and fluids to dedicated exits, situated at the bottom. The direction where the products exit is flexible and can be set into 3 different directions.

33 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT