- Nuevo

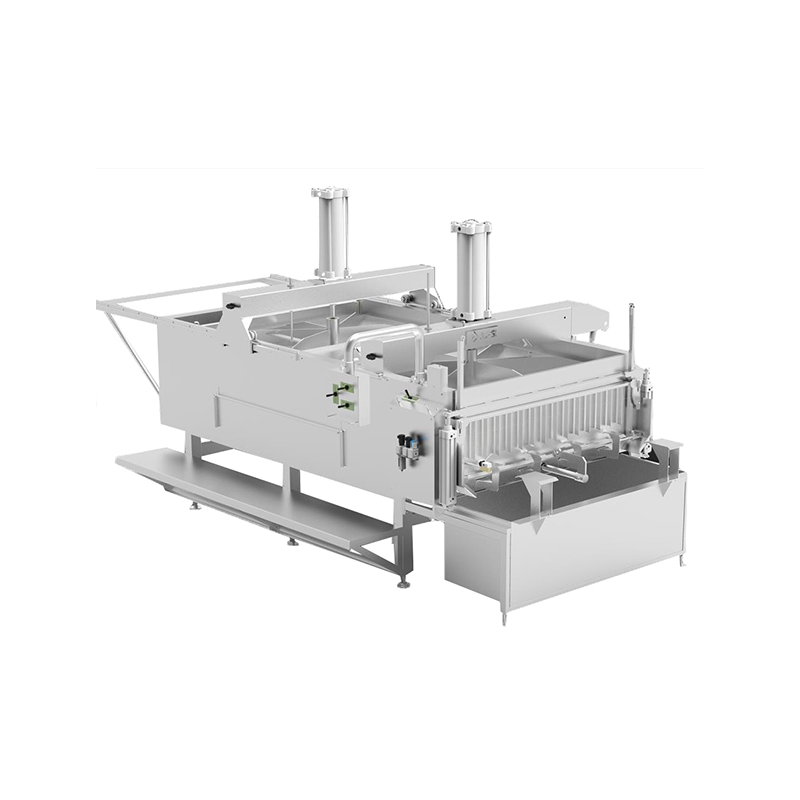

Horizontal forming machine

Cheese curd reception and shaping into the layer, whey removal and cheese layer cutting into bars

Descripción

Capacity for cheese mass - 500 and 1000 kg

Minimum curd loss

The required layer length and height

We will manufacture and customize the equipment for your technical requirements

In the forming machine, adjustment of the curd layer length is provided by shifting the movable rear wall when setting up the machine. This allows you to get cheese bars of the desired height while reducing the amount of cheese mass.

Automatic stopping of the layer extension is also provided by means of a pneumatic limit switch and obtaining bars of the required length when they are transversely cut with a wall-knife.

Minimum cheese curd loss

Cheese curd losses are minimized by reducing the gaps between moving parts and bath walls through which leakages occur.

Pressure accuracy

The equipment provides the required pressing pressure using larger diameter of pneumatic cylinders (160 mm). This pressure is smoothly regulated using filter regulators and is easily monitored by a pressure gauge.

Minimum manpower

For maintenance of the device, only one operator is needed, who sets up the device, controls it and controls its operation. Manpower is minimized.

Optimized work area

Cross head of two types allows you to maximize the release of the working area of the device when pouring raw materials and sanitary processing. The clamps pressing the layer are fixed on the rods of the pneumatic cylinders and do not require their manual installation

The control panel can be rotated and installed in a needed position for the operator.

Enhanced security

Enhanced security of machines operation by eliminating the use of electricity and the use of special devices for unloading cheese bars.

Characteristic |

AF-500 |

AF-1000 |

|

Bath capacity according to cheese mass |

500 |

1000 |

|

The total surface area of the filter plate |

3.5 |

7.0 |

|

Layer thickness |

80...240 |

80...240 |

|

Compressed air pressure |

to 0.9 |

to 0.9 |

|

Pressure on the layer |

to 11 (0.11) |

to 11 (0.11) |

|

Internal dimensions of the bath |

2800x1400x520 |

5400x1400x520 |

|

Dimensions, mm |

3750x2500x2550 |

6850x2500x2580 |

|

Mass, kg |

1400 |

2800 |

103 otros productos en la misma categoría:

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

Automatic meat ball and fish ball making machine (FMB-60)

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

- Nuevo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT