- Nuevo

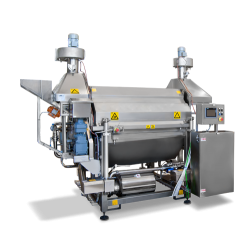

RotaTherm Direct Steam Injection Continuous Cooking

Direct steam injection cooking processes a higher volume of higher quality product in less time than a batch cooker.

Descripción

A continuous cooking system, compared to batch cookers, offer a variety of features that ultimately allow you to produce a cleaner, higher quality product, to do so more efficiently, and to reduce waste and energy usage.

Direct steam injection cooking processes a higher volume of higher quality product in less time than a batch cooker. A batch cooker has a fixed volume whereas a continuous cooker has high turn down.

The RotaTherm® is the choice for global food processors and manufacturers, and its value is enhanced by the following key manufacturing features:

- Non-stop production capability of up to 156 hours (or 6.5 days)

- Flexible parameters to easily adjust cook temperature, heating profile, pressure, and cooling temperature

- Fully enclosed hygienic system resulting in improved product safety

- Full clean-in-place (CIP) system requires minimal intervention

- The RotaTherm® is a continuous cooking system that produces a consistent and high-quality product, returns a positive investment and reduces and minimises wasted product, day after day.

- Its flexible production parameters can be set to maintain particulate integrity (up to 25mm), create homogenous product, or balance ingredient utilisation and end results by establishing optimal set up.

It is capable of production rates from 50 to 17,000kg per hour, dependent on your specific production needs.

Decades of experience, plus a highly skilled and educated food production and engineering team, solidifies the Gold Peg team as world leaders in direct steam injection cooking.

Why RotaTherm®?

RotaTherm® performance

Fast Heating

The RotaTherm® Direct Steam Injection Continuous Cooker can heat to your aim temperature in approximately 15-20 seconds.

Thorough & effective heat treatment

Once at the required temperature, your product can then be held precisely at the correct heat so that micro-organisms are eliminated in accordance with pasteurisation or sterilisation (UHT) procedures.

Long run times in hygienic enclosed system

Due to superior design, the RotaTherm® continuous cooker is able to operate continuously for 156 hours before full CIP. It can cook to temperatures over 100°C and, importantly, is a totally enclosed hygienic system. This means your product is not exposed to the environment once it has continuously fed into the cooker. The RotaTherm® is provided standard with a CIP system to clean the system on the few occasions you need to!

Benefits

The RotaTherm® Continuous Cooking system is all about introducing greater efficiency into your production process at the same time as delivering exceptional quality product.

This sophisticated piece of industrial cooking and processing equipment is loaded with intelligent thinking and boasts:

- A capability for non-stop production of up to 156 hours – meaning you get increased productivity and improved yield.

- Heating energy is directly injected and fused with product – making it an extremely efficient cooking system to run.

- A super-quick 15-20 seconds to reach its cook set point – meaning reduced processing time.

- Leading-edge technology that delivers accurately controlled cooking and processing.

- Versatility – you can easily adjust and set the cook temperature/heating profile/pressure/mechanical working on product.

- The capability to produce highly consistent product with a lower formulation cost and better density control.

- Pause control – so it is possible to interrupt flow without waste or rework.

- Intelligently designed to require minimal maintenance and have a small physical footprint (1m x 1m).

- Shorter product exposure to heat treatment – resulting in improved product quality, fresher appearance and flavour, plus a cleaner palate.

- Pasteurisation and Sterilization / UHT are achieved through super-efficient even heating –which delivers improved bacteriological results and therefore improvements in product shelf life.

Capabilities

The RotaTherm® continuous cooker has been designed to be able to take on even the most demanding production process with ease. The Direct Steam Injection RotaTherm® Continuous Cooking system capabilities include:

- Pasteurisation, UHT / Sterilization and Aseptic capability.

- Temperature-managed surfaces in high temperature zones.

- Throughput rates of 150 – 17,000+ kg/hr.

- Cook temperatures up to 145°C.

- Non-stop production capability of 156 hrs.Viscosity management capability.

- Control over the work on the product.

- Self-diagnostic capabilities.

- Large turn down ratio.Conforms to USDA and CE standards.Particulate management capability: can maintain integrity of particles up to 25mm.

The following percentages are further confirmation of the RotaTherm®'s standout food processing advantages over other systems.

- Waste: Up to 30% reduction in current waste

- Weight Control: Up to 25% reduction in overweight

- Moisture: Up to 0.5% increase in target moisture

- Formulation Cost Reduction: Up to 10% reduction in formulation cost

- Productivity: Up to 30% increase in productivity

- Labour: Up to 30% reduction in labour content

- Cleaning Chemicals: Up to 60% reduction in cleaning chemicals

*Above percentages are based on our previous installations of the Direct Steam Injection RotaTherm® Continuous Cooking system.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT