- Reliably macerates fibers and foreign matter in liquid media

- Protects downstream system components from damage caused by foreign matter

- Prevents blockages and clogging of pumps, fittings and pipe systems

- Reduces the viscosity and homogenizes liquids and suspensions

- Prevents floating layers

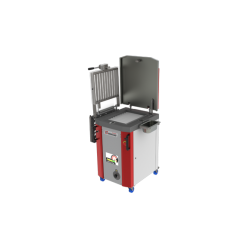

Vogelsang uses its proprietary software to develop cutting screens with optimized geometry for every size-reduction ratio. For operators, this means the best geometry at all times for smooth running, with minimal wear. The cutting screens are produced from wear-resistant special steel and offer twice the performance since they are reversible.

The cutting screens are exposed to high loads in cutters like the RotaCut. This is why in the RotaCut, they are not merely supported at several points, but rather their entire surface lies on a stable holder. This reduces deformation of the cutting screen and enables easy and energy-saving cutting across the entire surface.

Cutting blades and rotors have a decisive impact on the RotaCut's cutting performance. The asymmetric blade rotors we developed in-house deliver optimal shredding performance with minimal wear. The mobile bearing of the cutting blade ensures continuous contact between the cutting screen and blade – a solid foundation for reliable cutting of even the finest fibers.

Each RotaCut has a blade adjustment function that ensures that the cutting blade and screen are always in direct contact. This contact is what enables reliable shredding of even the finest, long-fiber fibrous matter, such as hair, industrial fibers and grass entanglements.

All RotaCut products feature a maintenance and easy to maintain design. Just a few motions are required to gain access to the cutting tools, which can be replaced on-site. The RotaCut is ready for use again in no time at all. The RotaCut does not need to be removed nor the cutter head disassembled.

OPTIONS

- Cutting screens

- The hole pattern of the cutting screens, along with the number of cuts, is decisive for the size-reduction ratio. To meet the requirements of every situation, we offer cutting screens for the RotaCut, depending on the size, with free passage from 4 mm to 50 mm. Stainless steel versions are available for aggressive media.

- Automatic Cut Control (ACC)

- The Automatic Cut Control (ACC) automatically adjusts the RotaCut's blades and maintains constant pressure between the cutting screen and blade. Moreover, the pressure can be adjusted during operation; as high as necessary and as low as possible. This extends the lifetime of the cutting blades and screen, and enables automatic operation.

- ACCplus

- ACCplus further reduces the cost of maintenance and monitoring of the cutter. It monitors the cutting blade status online and displays it on an external display. This means it's no longer necessary to place the cutter out of service and open it to determine the cutting blade status. Additionally, this information can be processed and displayed by the (central) control and/or remote control.

- Auto-Reverse function

- The Auto-Reverse function detects blockages, such as those caused by coarse disruptive matter, and initiates corrective action. By periodically reversing, the function further ensures that a pair of sharp cutting edges is always used while dull ones are sharpened on the opposite site. This delivers optimal cutting performance with reduced power consumption.

- Heavy material separator

- For smooth operation of many biogas plants, reliable foreign matter separation of stones and metal parts is a must, in addition to shredding. The adapted design of the heavy material separator is crucial. It has to be compatible with the requirements for the respective application as well as shredding. The RotaCut offers the most comprehensive selection of heavy material separators.

- Debris Removal System (DRS)

- The Debris Removal System (DRS) available for the RotaCut RCX series enables regular removal of separated heavy material during ongoing operation. The system removes the heavy material with only minimal loss of medium (only around 15 l). In comparison to conventional solutions, the DRS reduces the work required by 80%.

- Materials

- The housing of the RotaCut is made of steel and is completely galvanized. Stainless steel variants are available for particularly aggressive applications. Cutting screens and blades are also available in steel and/or stainless steel versions.

Hydraulic or geared motors adapted for the prevailing conditions of the application are used to drive the cutter. A selection of geared motors with various power ratings and different speeds are available for every type, so the RotaCut can always be individually adapted to the respective application. The perfect motor is available for every task, from protection against fibers and coarse matter through to fine, homogeneous disintegration of a suspension. Suitable cutting screens and blade rotors are available for individual adjustment of the size-reduction ratio from simple system protection through to homogeneous treatment.

The RC series RotaCut are the tried and tested basic version of the RotaCut. With flow rates up to 600 m³/h, they deliver reliable and economical shredding of fibers and disruptive matter in straightforward applications, and also separate heavy material, thereby protecting downstream parts and components from damage, blockage and entangled material, e.g. in waste water technology and industry. Thanks to diverse options, the RC series can be individually configured for the respective task. From cost-effective straightforward pump protection for temporary use through to reliable disintegrating of media in everyday operation. For drive power, there is a choice between hydraulic and geared motors. Thanks to the pivoting cutter head, maintenance and checking the cutter head is always easy, and if needed, the cutting blades and cutting screen can be quickly replaced.

APPLICATIONS

- Waste water

- Flotation tailings

- Disposal & Recycling

- Sludges

- Liquid manure

- Food industry

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT