- Neuf

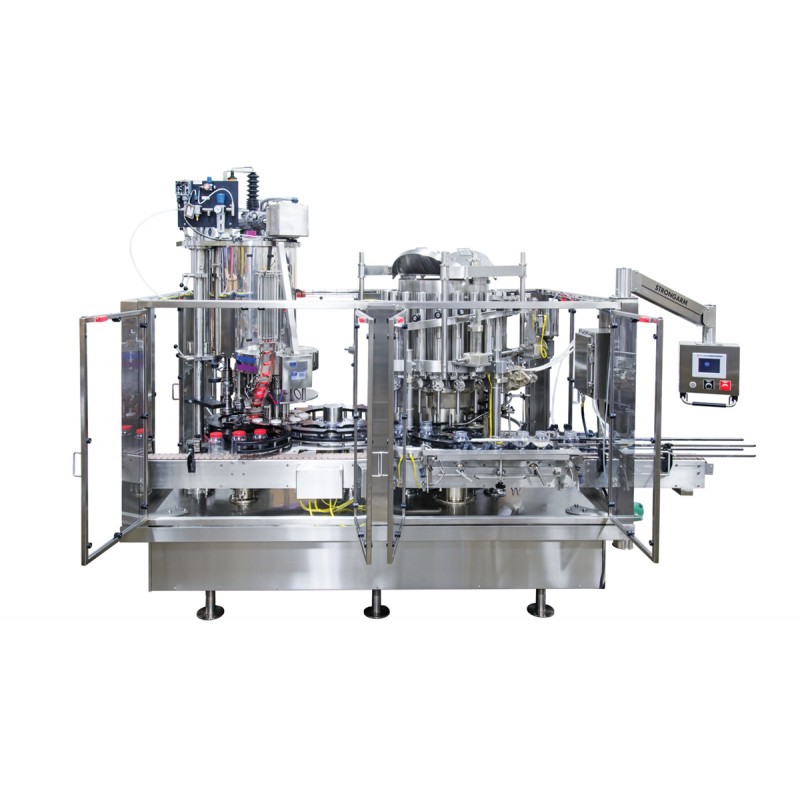

Dual Discharge Monoblock Filler for filling

Monoblock fillers for filling plastic, glass or metal containers.

Description

Elmar offers the custom design & manufacturing of monoblock fillers for our clients who need to fill plastic, glass or metal containers. All Elmar Monoblock Units are powered with an AC inverter motor control. This allows an infinite range of speed regulation on the Elmar control panel. Direct worm gearbox drives all turrets and stars. Each monoblock filler comes with our 1 year machine warranty.

Safety Features

An electronic torque-limiter guards against dangerous overload conditions if a jam were to occur. Special sensors strategically placed in the Monoblock system help to ensure a constant flow of containers including no container/no fill, no container/no cap, wrong way container detector/ejector, low cap chute, low cap hopper, etc. Custom computer electronic line control systems are available.

Custom Design & Built

Elmar custom designs each monoblock filling machine to meet all of our customers’ needs. Information needed to prepare an accurate quotation of your machine includes:

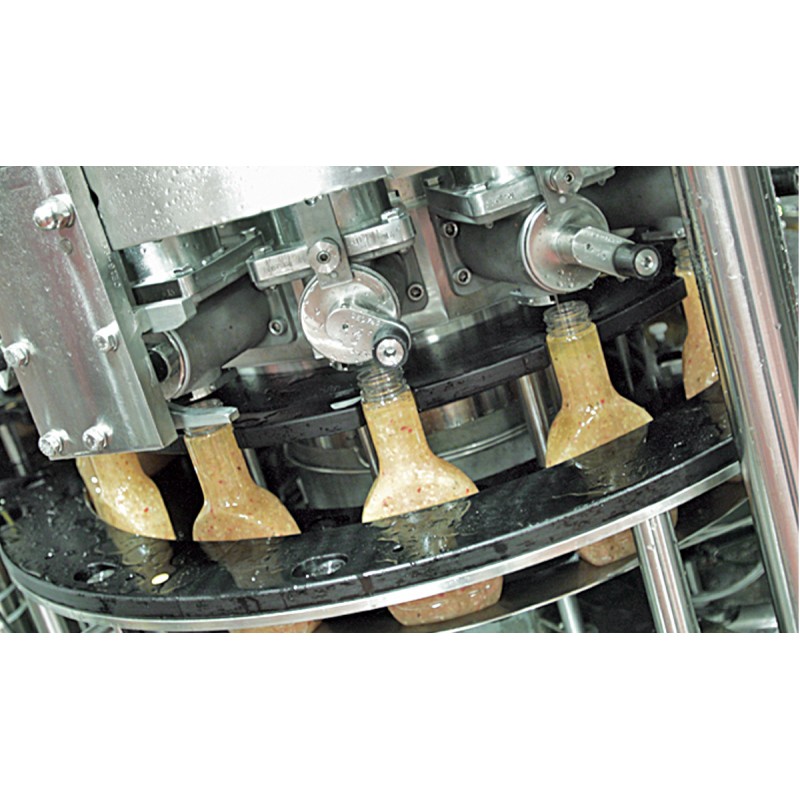

Container Information – we will need a sample drawing of each size container along with the type of material (plastic, metal, glass or composition), the diameter, height and size of the opening

Product(s) to be filled/capped – i.e. if Monoblock is to be used for more than one type. We will have you forward samples in the Filled/Capped condition. Where possible, we will have you indicate filling temperature, viscosity, and specific gravity

Sample/Size of Cap – whether the cap is a roll-on, snap or screw type

Containers per minute to be filled/capped

220 autres produits dans la même catégorie :

- Neuf

TPM 1000 fully automatic thermoforming packaging machine

- Neuf

- Neuf

- Neuf

DABL series automatic aseptic plastic bottle filling and capping machine

- Neuf

- Neuf

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- Neuf

Vertical form-fill and seal machine of the “Economy” series

- Neuf

- Neuf

- Neuf

- Neuf

Filling and seaming groups for aluminium and tin plate cans

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

AUTOFLOW Automatic Bag in Box and Stand Up Pouch Filler

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

GF series automatic plastic bottle filling and capping production line

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT