- Neuf

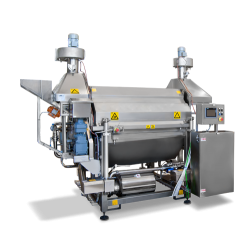

SUPER-WAKADAISHO All-in-one model WB874AS

The "SHINUCHI" noodle machine series has been embraced by the markets, helping to boost Yamato's market share to No. 1.

Description

Amaze Your Customers With Superb Udon Noodles

Making Authentic Japanese Noodles Has Never Been Easier!

No experience necessary!

A Noodle-making Master in the Shape of a Machine

The "SHINUCHI" noodle machine series has been embraced by the markets, helping to boost Yamato's market share to No. 1

Until Yamato introduced the “Shinuchi” series (Model S-1284) of noodle-making machines, most Japanese noodle lovers thought handmade noodles, called Te-uchi in Japanese, always beat out machine-made noodles when it came to taste, texture, smoothness and elasticity.

That has changed thanks to the hard work of Yamato founder Kaoru Fujii, formerly an. engineer of mechanical design. Fujii began analyzing traditional Te-Uchi udon-making methods from an engineer’s perspective. He gave himself entirely to studying the secrets of good noodle making and used his scientific background to understand why certain methods were more successful than others. He then translated this research into the design for the company’s noodle-making machines.

Now, 30 years and more than 1,300 refinements later, the Shinuchi series machine is nothing short of a noodle-making master in the shape of a machine. It successfully combines the essence of traditional noodle making with the most advanced digital technology.

Here’s why a Shinuchi Udon-making machine is an excellent addition to any noodle shop or restaurant:

- Consistently produces high-quality noodles

- Requires no noodle-making expertise or experience

- Boosts productivity (100 portions or more per hour)

- Has a small footprint for easy in-store installation

- Protects operator from injury with its auto-shutoff safety device

- Is made of stainless steel for hygiene and ease of cleaning

Fresher, Better Noodles

The secrets of fresher and better udon noodles made by Shinuchi, noodle making machines lie within production processes and mechanics of the machine, combined with Yamato Noodle Making Methods. To make authentic noodles with distinctive textures, it needs separate equipment, such as aging machine for processes, called “aging” or “resting”.

1st day – 1. Mixing | 2. Resting/aging (1st aging) | 3. Pressing | 4. Resting/aging (2nd aging)

2nd day – 5. Thinning (by roller) | 6. Cutting | 7. Portioning (manually)

Versatility

SHINUCHI noodle making machine is good at making noodles that are high in water content, which makes noodle texture soft and chewy.

This machine is equipped with all functions to make many types of noodles, but it cannot make such noodles as dry noodles like certain types of ramen noodles. (For example, thin and hard ramen noodles, typically called, Hakata Tonkotsu Ramen noodles cannot be made on this machine) Unlike ramen machine, this machine uses cutter blade to cut dough into noodles at widths that can be adjusted by control.

Compact / Show

Because Yamato Noodle Machine is designed to fit and work in environment where space is scarce, the machine is compact to fit in a kitchen, taking up small space.

It is also designed with stainless steel covers and casings to show how it works and makes noodles to customers. There’s a growing trend restaurants show how they make their fresh noodles to customers.

Min. required space: It is possible to operate the machine, but it is very tight and may be difficult for a person of large build. And, even for a person of standard build.

We help draw floor plan for your restaurant for efficient operation. If you can provide such information as measurements of the location and menu items you are going to offer, we can help you make a layout with consideration for effective and efficient operation.

Ease of Use

Ease of use is very important for noodle machine because it is used to make fresh noodles to be served every day. Operation should be as easy as it is incorporated into daily routine tasks.

Noodle Thickness display

Measures and displays thickness of dough being thinned in rolling process. It allows the user to check it for the right thickness with a glance at the display.

Roller gap adjusting handle

The roller clearance can be adjusted with this lever. It is like shifting of gears, starting from the bottom (thickest) to the top (thinnest).

Clear mixer lid

The condition of dough being mixed can be checked without opening the lid as it can be seen through the lid. And, water can be added directly onto the lid.

Noodle lining tray

Cut noodles automatically fall onto this moving tray, collecting and lining noodles nicely. When finished, noodles are lined in a way that is easy to portion out manually.

- Outer dimension: W 1,120 x D 840 x H 1,330 mm

- Weight: approx. 400kg

- Mixer & Press Capacity: 8kg (flour)

- Output (servings/hour): 150 – 200

- Power supply: Single Phase 100V Japanese model

77 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT