- Neuf

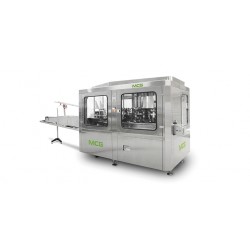

Can seamer F12-2

For aluminium beverage cans as well as steel and plastic applications. Capacity range of 34'800 to 105'000 cans per hour.

Description

Features

Entire seaming area in stainless steel

Quick changeover system for a quick format change

Automatic speed-dependent undercover gas flow regulation

Utility tower and integrated cleaning system for most stringent hygiene requirements

Increased precision for applications with light-weight cans and end material

Easy operation and cleaning

Minimal effort required for maintenance

24-hour non-stop operation

Maximum safety for the operating personnel

Equipment F12-2

The can seamer F12-2 is equipped with the following standard features:

Synchronized infeed table

Quick changeover system for a quick format change

Complete tool including seaming roll Easy Rider

Undercover gassing automatically regulated

Bubble breaker

Disengageable seaming cam 2nd OP

Electric oil pump with loss-free centralized lubrication and oil flow monitor

In-motion-timer, motorized

Slow motion, motorized

Motorized can height adjustment with digital display

Interior illumination of machine

Integrated cleaning system

2 end feeds

Filler drive with overload clutch

Chain drive with spring clutch

Air treatment unit (compressed air system)

Can discharge table incl. discharge turret and deflection wheel

47 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

DABL series automatic aseptic plastic bottle filling and capping machine

- Neuf

- Neuf

Automatic inline bottle capping machine model TruCap-X-Vert

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

GF series automatic plastic bottle filling and capping production line

- Neuf

- Neuf

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT