- Nuovo

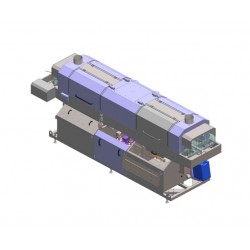

Pallet Box and Stacking Container Washer CLT PB

NIEROS® Pallet Box and Stacking Container Washing Machine CLT PB provides a thorough washing and drying of Euro pallet boxes and their lids.

Descrizione

NIEROS® Pallet Box and Stacking Container Washing Machine CLT PB provides a thorough washing and drying of Euro pallet boxes and their lids, Euro-pallets, stackable tanks, containers and other items of adequate dimensions.

CLT PB can accommodate up to 50 Euro pallet boxes or similar items per hour with a size limit of 1250 x 1250 mm per item. The blow-off function is integrated into every CLT PB unit.

The washer can be integrated into the conveying system with the items in stacks being loaded onto the conveyor, separated and turned around so that they can be thoroughly washed. It is a perfect solution for any industry in favour of automatic washing and drying of Euro pallet boxes with or without lids, Euro-pallets and other similar items.

Product specifications

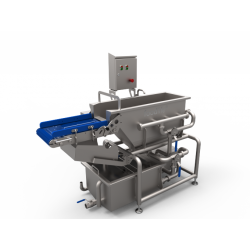

Pre-washing, washing and rinsing zone

Tunnel washing machine

Suitable for Euro pallet boxes and lids, Euro-pallets, stackable tanks, containers and other items of adequate dimensions

Washing capacity of up to 50 items per hour (depending on the model)

Blow-off function

Object detection sensor in the rinsing zone

Stainless steel DIN 1.4301 (AISI 304) transport chain

Easy and convenient access to spray nozzles and water tanks

Features

Washing and rinsing zone

Stainless steel DIN 1.4301 (AISI 304)

Electric water heating

Adjustable washing and rinsing parameters

Automatic detergent dispenser

Smooth surface finish

Height adjustable

IP65 protection

Electrical connection

Object detection sensor in the rinsing zone

Stainless steel DIN 1.4301 (AISI 304) transport chain

Easily adjustable sideguards and hold-down attachments

Adjustable nozzles

Sustainable Solutions

Water recycling system effectively reduces water consumption by reusing fresh rinse water in other cleaning phases. The machine collects the rinse water to make it available either for a pre-washing or cleaning phase. As a result, the machine consumes significantly less freshwater in both these phases.

Double filtering system prolongs the pump’s lifespan by ensuring that the double-filtered water flowing through the pump contains no dirt particles.

Low water level protection stops the machine in case of insufficient water level in the system, preventing damage to the pump and heating elements that could appear in case of dry operation.

Options

Fully customized washing machine

DIN 1.4404 (AISI 316 L), DIN 1.4571 (AISI 316 Ti) or other chemically more resistant stainless steel

Adaptation to local electrical standards

Steam water heating

Additional electric flow heater (when rinse water is too cold)

Sanitization with 85 °C hot water

Sanitizer dispenser

Vapour extraction fan

Rotary drum filter for larger dirt particles

Belt filter to remove particles smaller than 2 mm2

Basket for utensils and small parts

Mesh conveyor belt

Left/right position of command keys

Pallet washing

Touchscreen control panel allowing remote access

118 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

INDUSTRIAL PASS THROUGH WASHER FOR CRATES, UP TO 100 PCS/H

- Nuovo

- Nuovo

- Nuovo

Tank cleaning system Risto - Wash 2013

- Nuovo

- Nuovo

Industrial washing-machine & forced air drying module

- Nuovo

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Perfectly clean vegetable crates thanks to unique Pivo system

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

INDUSTRIAL WASHER FOR 200 L BUGGY WITH STANDARD FILTER

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT