- Nuovo

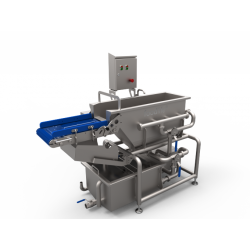

VACUUM CHAMBER

Unit used to saturate champignons with water or other preservatives to defined technological parameters.

Descrizione

Vacuum chamber

- Vacuum system (pomp with water tank, seal off valve, pressure sensor)

- Solution feeding system (water pomp, seal off valve, water level sensors)

- Pressing system (pressing grill, pneumatic servomotor valve)

- Air valve Power and control valve (with microprocessor PLC)

- Working signal system (lights) Pneumatic control and power supply system.

Solution tank

- Tank with hatch

- Maximum water level sensor

- Water dozing sensor

- Seal off valve

Platform for service

Concentrate tank with optional automatic batching system Sliced or full mushrooms in boxes with covers are putted into the chamber. After closing the door, pushed the start button the unit is starting to work. Work cycle and each one of recipes can be set from CONTROL PANEL. The chamber has the water solution getting inside the product under the pressure. After the end of the process the water solution is pumped out from the chamber.

Construction made from the stainless steel. Parts which are in direct contact with the food are made from materials approved to contact with the food. Unit is easy to clean. Electrical control placed in waterproof box.

TECHNICAL INFORMATION

- Working chamber size (width. x height. x depth.)

- -1 box-pallet...KV1….1300 x 1250 x 1000

- -2 box-pallets...KV2…1300 x 1700 x 1000

- -4 box-pallets....KV4…1300 x 1700 x 2000

- Tank capacity 6 m3(KV4)

- Capacity (3-4) cycle/hour.

- Box-pallets capacity (250-350) kg. champignons

- Power demand 6,2 kW , 14 A(KV4)

- Power supply 3 x 380 VAC, 50 Hz

- Control panel with time clock (controlling programmed in PLC )

- Made from stainless steel AISI 304

Steel which is in contact with solution AISI 316 L Maximum vacuum 150hPA

36 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

PEF Advantage B 1, B 1 mini, 10, 100 & 1000

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT