- Nuovo

INJECTOR

Contract price

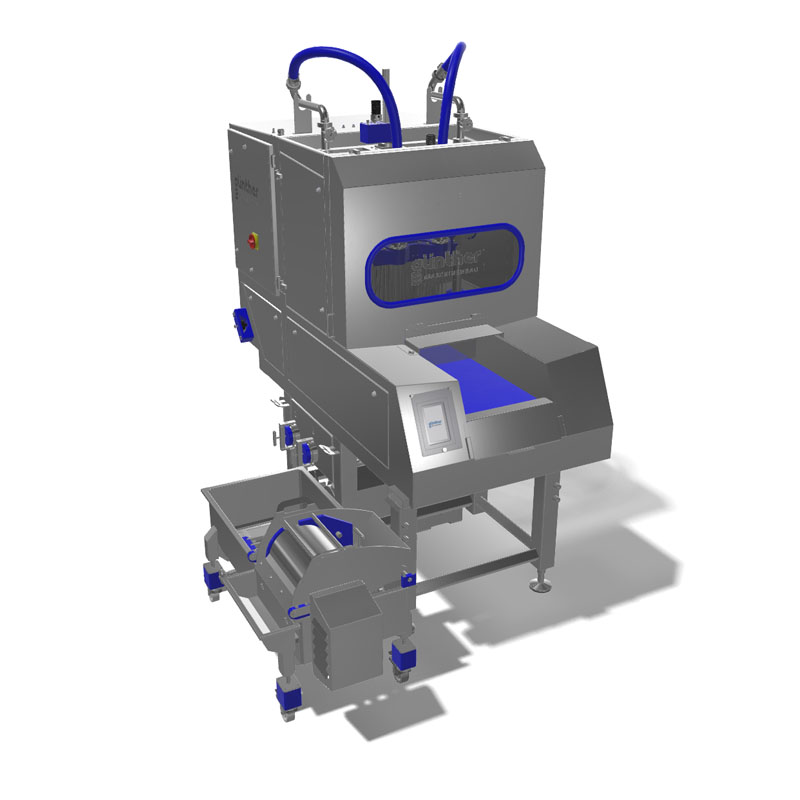

MACHINES FOR INJECTING BRINE INTO BEEF, POULTRY, FISH AND CHEESE

UPC:

EAN13:

Nuovo prodotto

Venduto da:

Descrizione

You always get the best out of your procuts - better still you inject them! The brine injectors from Günther Maschinenbau enables you to always have the perfect tool to refine your products - whether for with spices, additives or special features which only you know. Add increased shelf life and taste to your products by working with a well-designed, durable machine with the highest-possible standards attained by over 40 years of experience in the foodstuff industry.

Your benefits

- Taste improvement by utilising injected flavours and taste enhancers

- Improved colour tones and handling by utilising injected salts

- Uniform reddening and shelf life

- Better product consistence

- Higher yield when slicing

- More juicy consistency for the final product

- Higher yield and increased profit

Application scope

| Pork | Beef | Poultry | Fish | Cheese |

| ✓ | ✓ | ✓ | - | ✓ |

Machine details

| Belt width in mm | 365 |

| Needle designs | 54/75/105 |

| Capacity* in kg/h | 4052 |

| Product clearance in mm | 220 |

| Strokes in 1/minute | 50 |

| Dimensions in mm (length/width/height) | 1800/1000/2500 |

| Connection data | 6,5KW 16A 400V 3PH/N/PE |

| Compressed air | 6-8 bar |

Fixtures:

- Stainless steel centrifugal pump - additional pumps for higher viscosities on request

- Pre-filter system for protection against clogged needles with electronic monitoring

- Special conveyor belts with foodstuff approval

- 1-fold, 2-fold and 3-fold stitch adjustable via control system for optimum brine distribution

- Includes rapid exchange for needle beam system

- Pneumatic, individual needle suspension to protect against damage

- Complete separation of the brine circuit from electrical and mechanical components in order to minimise the heat input to the brine

- Individual process parameter settings possible

- Double head design possible

- Additional options on request

* Averaged value (for boneless product/ injection rate 20%/ 120mm throughput)

19 altri prodotti della stessa categoria:

- Nuovo

Brine injectors - SM 30 / SM 60 / MM 104 / MM 104 DUO

- Nuovo

Line for industrial injection of chicken

- Nuovo

PREMIX FOR WINE AND GRAPE JUICES

- Nuovo

IMAX 420/520/620 – Walking beam injector

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT