- Nuovo

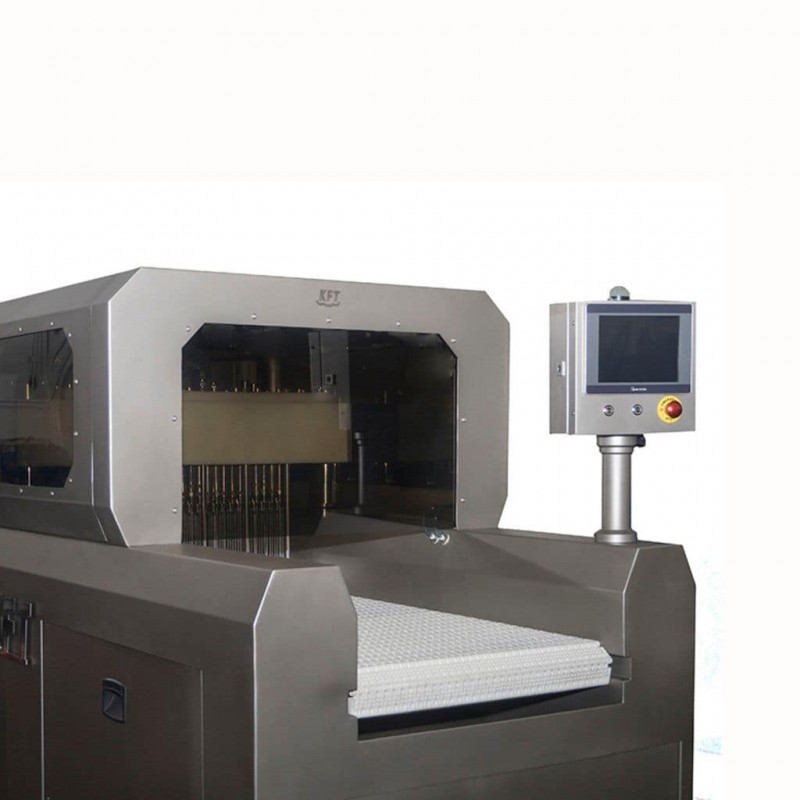

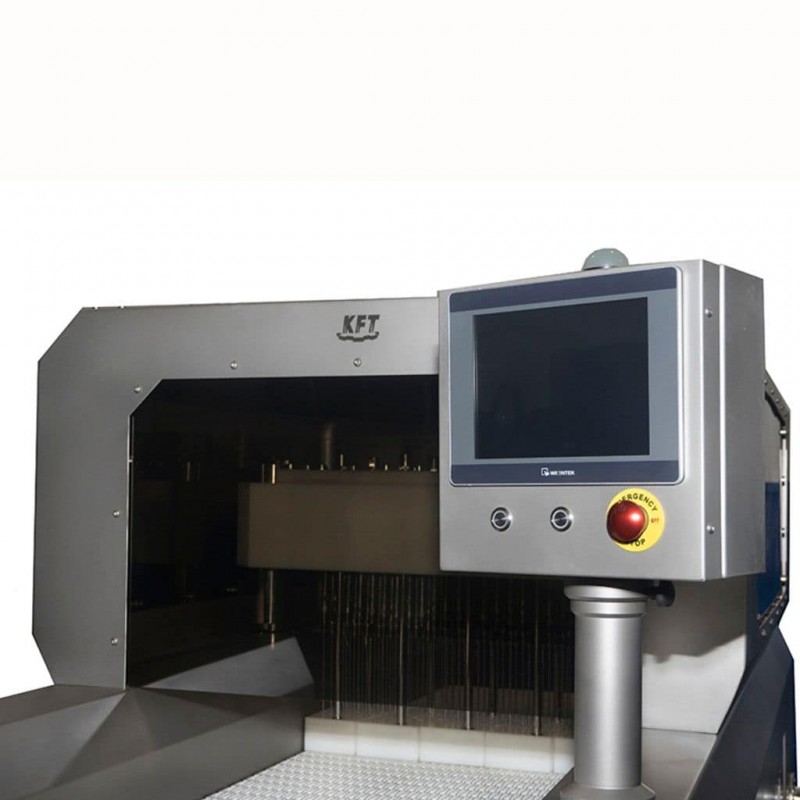

High pressure injector (Hydraulics)

The IRC spray injector created by KFT Food Technology is designed for the meat industry which requires strong reliability and high production; with excellent and unbeatable results in the processed product.

Descrizione

Característiques:

High productivity

Uniform distribution and invisibility injection into the product.

Spray injection technology, offers perfect distribution and homogeneity of the brine in the injected / marinated product.

The machine’s versatility allows us to work with different types of products; with or without bone, all kinds of meat even different types of fish and cephalopods.

The injection enhances the flavor

The injection improves texture

The injection provides the nutrients

The high pressure injection allows us to work in ranges from 2 up to 12 bar, depending the type of needle, and volume of product to be injected.

Poly-color touch panel for total interaction between the machine and the operator.

Recipe management, alarm, easy-maintenance, adjustment for injecting and transporting.

Security system in accordance with current regulations, equipped with an anti-entrapment system.

Injection system is provided with a hydraulic system, specially made with technologically advanced elements in the current market.

Remote support system in case of failure in order to solve a problem effectively.

Hygienic traction system.

Anti-spatter screen.

Filtering of solid particles in the brine tank.

Easy-click to change the needles: Minimum effort for changing needles.

Hygienic and easy-clean general design.

Redesigned collection of excess/remaining brine where it is filtered in an autonomous station; and reuses all the solution injected.

Optimal beyor load height for comfortable work position.

Constructed with the utmost rigor, down to the smallest detail using high quality material.

Automatic cover elevation for easy cleaning.

Internal self-cleaning program.

Monitoring system to ensure that there is no air in the brine in order to obtain final product quality.

The IRC injector spray may be configured:

· With discharge belt

· With direct connection to the tumbler.

· Line brine preparation, automated injection and draining.

· Multi-head.

· Incorporation of saber tenderizors.

· Self-regulation of injection percentage.

Building materials: 304 and 316L stainless steel

18 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT