- Nuovo

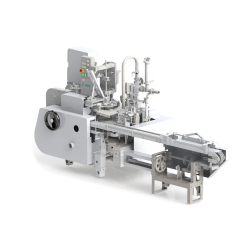

C100 Forming, filling and sealing for cups

The C100 is the compact, high quality entry machine for cups with a low output. This form, fill and seal machine stands for multiple food and dairy applications.

Descrizione

Maximum accuracy, excellent accessibility

A low output category machine, the C100 handles up to 7,000 cups per hour for all kind of dairy products as well as liquid-to-pasty food products. With a minimal footprint and a modular structure for convenient handling, the C100 is a simple and cost effective solution with only one press.

Thanks to optimised machine design and a simple, intuitive HMI, operational costs, as well as maintenance costs and downtime are kept to a minimum.

C100 Highlights

1. Small footprint.

2. Maximum accuracy, precise product cut-off and gentle product handling.

3. Servo driven dosing pistons for easy adjustments.

4. Large variety of cup shapes and designs

Products to be filled

With the form, fill and seal machine C100 you can fill all kind of liquid-to-pasty products - with or without particulates - such as yogurt, fruit juice, white cheese, desserts, pureas, etc.

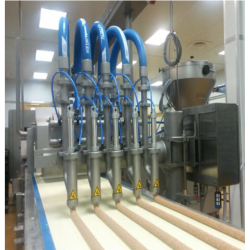

Filling solutions

With its' long term experience in filling liquid to pasty products into different kind of cups - in thermoformed as well as in pre-formed cups - Erca offers a large variety of different filling possibilities. The fillers are known for their outstanding filling accuracy, a factor which inevitably leads to minimal product loss and enhanced productivity. Covering a wide range of filling styles, countless customized and tailor-made design possibilities are available to satisfy specific requests.

Labelling solutions

Cups can be designed cost-effectively and with a huge variety of different labelling solutions. The label is not only a marketing instrument - it also improves the cup’s sidewall stability - making it more rigid so the bottom web thickness for the cup can be reduced.

Cup Shapes

Customized and tailor-made cup design possibilities are available to satisfy specific customer requests.

| TECHNICAL DATA C100 | |||

| Cup material width | 300 mm | Draw off length | max. 150 mm |

| Usable width | 284 mm | Forming depth | max. 80 mm |

| MATERIALS | |||

| All common packaging materials | |||

| Bottom web | PS and multilayers, PS/PE, PS/EVOH | ||

| OUTPUT | |||

| Yoghurt cups 63 x 63 mm with wrap-around label 1 x 4 | 7,000 cups / h | ||

| STANDARDS | |||

| Hygiene | Clean | ||

| Components | Controller and servo motors ELAU | ||

| Standard configuration | Bottom web reel Ø 400 mm Lid web reel Ø 300 mm Label reel N/A, plastic pulling by fixed and movable grippers, heating station: 6 pitches, dosing by membrane or piston filler (up to 2 units), semi-penetrant cutting tool: waste less punch for packs, exit conveyor with belt |

||

| OPTIONS | |||

| Hygiene | Ultra-clean | ||

| Fillers | Rotary valve filler | ||

| Labelling | Bottom labelling | ||

| Cutting unit | Individual punching | ||

220 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- Nuovo

- Nuovo

GF series automatic plastic bottle filling and capping production line

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

TPM 1000 fully automatic thermoforming packaging machine

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Filling and seaming groups for aluminium and tin plate cans

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- Nuovo

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

Vertical form-fill and seal machine of the “Economy” series

- Nuovo

- Nuovo

DABL series automatic aseptic plastic bottle filling and capping machine

- Nuovo

AUTOFLOW Automatic Bag in Box and Stand Up Pouch Filler

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT