- Nuovo

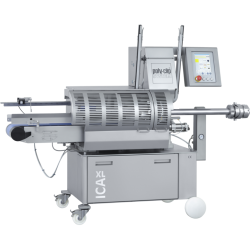

BDC200 MR two-row, rotary clipping machine

The BDC-200 MR rotary clipping machine is a new type device that is a development of the BDC-200 MT two-row table clipping machine.

Descrizione

It is an easy-to-use, universal and reliable device for fast closing of various types of casings with a diameter of 25 to 100 mm. It is perfect for packaging a wide range of products such as sausages and processed cheeses. Thanks to the standard stuffing pipe, combined with the adjustable casing brake and the rotating base, the clipping machine can be connected with the stuffer.

An additional advantage is the redesigned pneumatics, which allowed to increase clipping speed up to 10% - 20% per cent in comparision to MAGA PW-90 clipping machine.

Advantages:

a wide range of diameters of the clipped casings (25-100 mm)

a set of stuffing tube with a casing brake included in machine

clipping all casing types

possible to open, swivel base in the range of 60 and 90 degrees allows easy access to the stuffing tube and placing further casings without necessity of clipping machine moving on the table

a wide, low-mounted handle bar influences on proper and ergonomic operation

handy cutting knife valve

no need to use guide trays

large clips magazines and easy to clean

The above functional values, as well as constant and quick access to spare parts make working with our clipping machine easier, faster and very effective.

Klipsownica dwurzędowa rotacyjna BDC200 MR

Discover the possibilities of the BECK BDC-200 MR clipping machine:

automatic cutting of the casings into portions of the same size

smooth adjustment of the clips bending force

adjustment of the distance between the clips

special tool for stuffed casings length regulation

connection to the stuffer using a dedicated funnel equipped with a casings brake

clipping with a loop

clipping with one or two clips

possibility of developing to a semi-automatic machine

Optional equipment:

a device for clipping delicate casings (index B)

short stuffing spreader - enables clipping of large diameter bars (KB index)

automatic loop feeder (PP index)

automatic string feeder (PS index)

air preparation station

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT