- Neuf

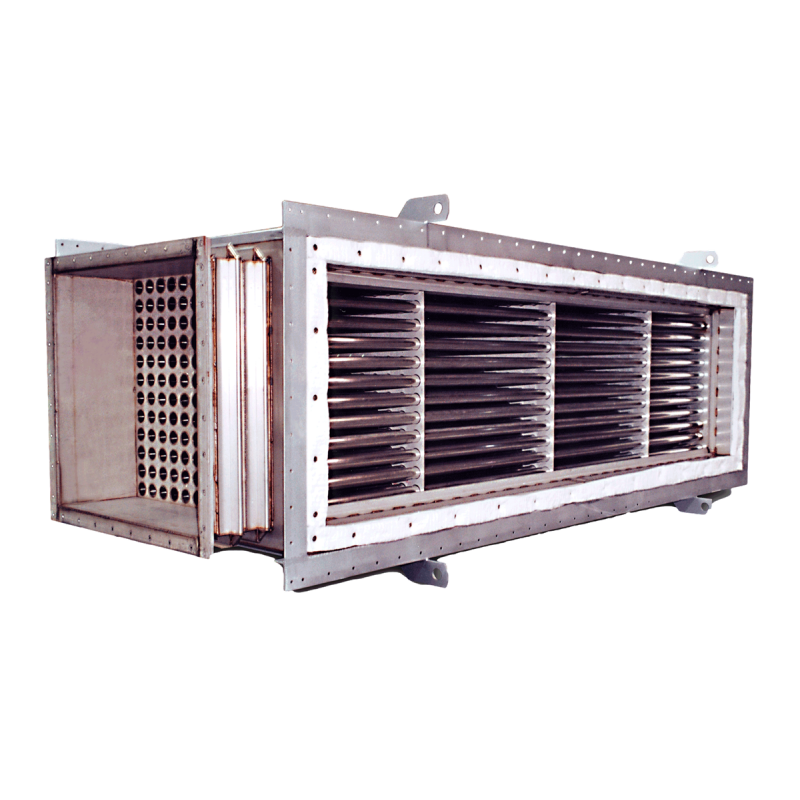

Thermo-T® Welded Tubular Heat Exchanger

Munters Thermo-T® High-temperature shell and tube heat exchanger.

Description

Munters Thermo-T® High-temperature shell and tube heat exchanger.

Features

• Standard operation to 1800°F; higher temperature construction available

• Effectiveness to 80%

• Pressure differentials to 28" W.C. standard

• Fully-welded construction

• Custom designs

The Munters Thermo-T tubular heat exchanger recovers heat from energy-consuming processes at temperatures up to 2000°F. Heat transfer tubes are fully welded to the tube sheets, ensuring minimum cross-contamination. Integral expansion joints make the Thermo-T ideal for high-temperature applications. Single and multi-pass models are available with effectiveness values up to 80%.

Thermo-T offers fully adjustable tube size and tube spacing. Combine this with the unmatched flexibility in materials of construction and flow patterns, and Thermo-T is the obvious choice for your high-temperature heat recovery application. To meet unique performance or configuration requirements, both single and multi-pass models are available. The Thermo-T can be integrated with a plate heat exchanger (Thermo-Z®) to provide the ultimate in effectiveness, reliability and value.

Construction

The Thermo-T heat exchanger is designed and constructed for an industrial environment. Proper material selection is crucial to the life of a heat exchanger. Typically, Thermo-T is constructed with 304L, 316L, or 309S stainless steel tubes and tube sheets. These materials provide superior performance in high temperature or corrosive environments. Optional materials are available to meet specific needs.

The tubes are fully welded to the tube sheet to provide a double layer of protection against cross-contamination. The tube size and spacing are fully adjustable at the time of manufacture to meet exact performance requirements.

The inner casing is constructed of the same material as the heat transfer matrix. It is welded to the matrix at certain peripheral locations to assure an air-tight seal.

Standard construction

• Fully welded tube bundle (.065 inch avg wall thickness)

• 1/4" thick tube sheet

• Tubes fully welded to tube sheet

• All-welded casing (minimum 0.105 inches thick)

• 2" x 2" x 1/4" pre-punched flange connections

• Highly effective counterflow pattern

• Ready to be field installed and insulated

Custom-engineered construction

• Broad selection of materials

• Insulated double-wall construction with integral thermal expansion joints

• Single & multi-pass units

• Designed to meet user requirements

• Complete systems

• Tube bundle cleaning options

• High-pressure construction

Applications

• Transfer process exhaust to process make-up air

• Cooling process air prior to baghouse

• Reduces peak electrical demand

• Rotary kiln

• Waste process heat to plant make-up air

Optional expansion joints with welded outer casing

Thermal stress is another major factor in high-temperature heat exchanger design. At high temperatures, Munters’ integral expansion joints allow the tube/sheet assembly to expand without causing excessive stress.

The outer casing remains cool because of the layer of high-temperature insulation. Therefore, it will not expand as a result of process temperature changes. The internal casing is secured to the cold outer casing by means of integral thermal expansion joints. These joints allow the inner matrix/casing assembly to move freely without undue forces being imposed on it by the rigid, cool external casing. The heat exchanger (with its cold flanges) can be installed flange-to-flange to the ductwork without the need to compensate for the thermal expansion of the heat exchanger.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT