- Neuf

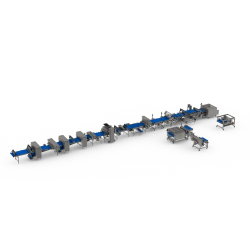

GPiCS mozzarella cooker stretcher

Gold Peg identified a need for an efficient cooker stretcher for sensitive products like mozzarella and pasta filata.

Description

Gold Peg identified a need for an efficient cooker stretcher for sensitive products like mozzarella and pasta filata. And so, the direct steam injection GPiCS was born!

Gold Peg’s GPiCS identified food manufacturers’ needs for not only for a direct steam injection cooking system, but one with adjustable parameters that could be adjusted for mozzarella’s sensitive nature and varieties.

The GPiCS Mozzarella Cooker Stretcher (Patent number US 8,875,623) is a world-class, innovative cooking system that produces a variety of natural mozzarella products. Its benefits include:

- Direct steam injection that efficiently cooks and heats the product

- Low-pressure steam injection reduces strain on sensitive cheese varieties

- NO bath cook water

- Precise temperature control

- The ability to add ingredients to the product stream inline

- Increased shelf life

- Faster CIP (clean-in-place) reduces downtime and increases production

It is also more environmentally friendly, as it doesn’t use lots of bath water that then needs to be reprocessed before it can be reused or disposed of. This reprocessing requires capital investment, and has huge costs. It is usually a separate operation unit within a business! This is not needed with the GPiCS.

Natural Mozzarella Continuous Cooking System

As a continuous cooking system, the GPiCS offers a range of features where traditional wet cooker-stretchers fall short.

Primarily, the GPiCS Mozzarella Continuous Cooking System works with no bath cook water, a feature that heavily improves quality, taste, density, and texture of the final product as well as the impact on the environment.

Further, with the GPiCS system, you’re offered the flexibility to add ingredients directly to the curd stream during cooking. From here, any additional ingredients are mixed into the existing curd flow during the cooking and stretching processes. The totally sealed system ensures no foreign matter is introduced to the stream.

On the other hand, traditional wet cookers are generally open systems, posing a high risk of foreign matter introduction. The addition of bath cook water means it is nearly impossible to add ingredients to your stream because they would mix away with the bath water.

How It Works

The GPiCS cooker stretcher is a low pressure, low shear, direct steam injection continuous cooking and stretching system for Natural Mozzarella production.

It is specifically designed for the sensitive nature of mozzarella and pasta filata curd.

It is a fully enclosed hygienic system, so the product is not exposed to the environment once it has been fed into the GPiCS mozzarella cooking system, which also makes ingredient addition possible. Read more benefits of the GPiCS.

Benefits

The direct steam injection GPiCS continuous cooker stretcher, for natural Mozzarella and pasta filata varieties, delivers the following benefits:

- NO bath cook water

- Ingredients addition

- Product quality: composition, sensory & functionality quality similar to traditional wet cooker product

- Start up/shut down losses 10% of a traditional wet cooker

- Faster CIP

- Continuous long runs to match curd supply

- Clean product free of burnt specs and foreign matter

- Flexibility to respond to the individual sensitivities of required specifications abd therefore produce a wide range of natural Mozzarella, String cheese and Pasta Filata formulas

- Automation - minimal operator requirement

- Huge reduction in loading on secondary processing of whey due to minimal losses

Capabilities

The GPiCS cooker stretcher, cooking equipment for natural Mozzarella and pasta filata varieties, has the following capabilities:

- Quality: composition, sensory and functionality similar to traditional wet cooker product

- Flexibility to process a variety of Natural Mozzarella, String cheese and pasta filata specifications

- High product safety and quality due to the enclosed hygienic design

- Flavours / liquids can be added in line to the product stream during processing

- Flexibility to respond to the sensitive nature and varying needs of the mozzarella / Pasta Filata

- Adjustable working and stretching modules - individual and independent adjustable control

- Automation

The GPiCS is for pressure and shear sensitive products of high viscosity that are not readily flowable or pumpable (cannot be pumped or do not respond well to being pumped) and have varying hold time requirements.

110 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Artificial Rice Extruding Line / Instant Rice Making Machine

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT