- Neuf

MASSTERMATE

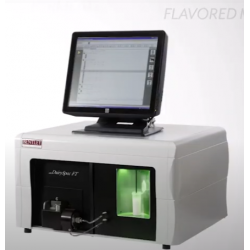

Au2mate MASStermate standardisation unit is applied for automatic high accuracy standardising of the fat percent in the cream and the milk line after a milk separator. The standardisation unit can be applied in new as well as existing installations.

Description

The standardisation unit can operate as stand-alone or seamlessly integrated with a factory control system. The unit is pretested and delivered ready to install in the dairy plant.

BASE CONFIGURATION

Au2mate MASStermate standardisation unit is pre mounted, wired, and tested on frame and includes the following equipment:

- Control panel (Siemens or Rockwell solution available)

- 2 pcs mass flow transmitters

- 1 pc flow transmitter

- 2 pcs regulating valves

- 2 pcs process valves

- 2 pcs manometers

OPTIONS

- S88 integration with factory system

- Interface to milk analyser

- Tank standardisation

- Connectivity for remote service

TECHNICAL DATA

• Stainless steel pipes & fittings AISI 316

• Siemens or E&H flow transmitters

• Samson regulating valves

• SPX or Alfa Laval valves

• Siemens or Allen Bradley control equipment

• Accuracy milk standardisation 0.02g/100g

• Accuracy cream standardisation 0.15g/100g

• Test procedure according to standard distribution

- 68.2% of samples within +/- 0.020g/100g

- 95.4% of samples within +/- 0.040g/100g

- 99.7% of samples within +/- 0.060g/100g

• Test to be conducted under stable process conditions

• Milk temperature 45-65 degrees Celsius

• Ambient temperature 0-30 degrees Celsius

• Power supply 240 VAC

• Control panel protection degree IP 55

34 autres produits dans la même catégorie :

- Neuf

- Neuf

GF series automatic plastic bottle filling and capping production line

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT