- Neuf

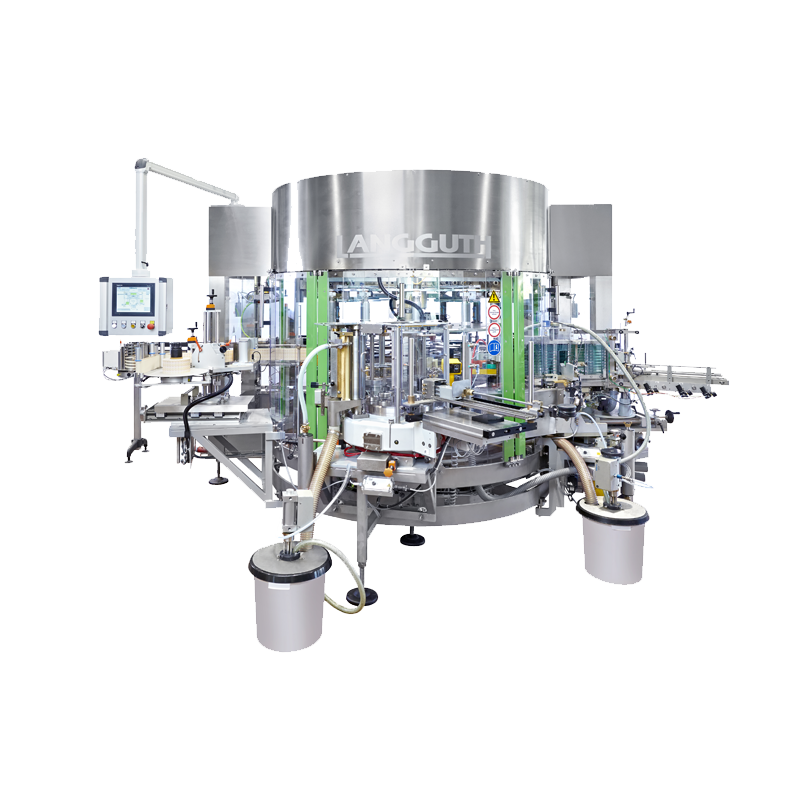

moduLAN 800

For almost limitless flexibility LANGGUTH offers its moduLAN rotary labeler

Description

Customers appreciate the opportunity to select a combination of label types using single modules, multiple modules, or combination modules. The moduLAN is offered in three different speed ranges.

Advantages:

Highest engineering quality

Labelling modules can be combined

Tool-less changeovers with quick release components

High operator accessibility and easy cleaning

Wet glue stations use LANGGUTH’s direct label transfer FVT18 magazine without glue pallets

Versatile and simple operation

Maximum flexibility and customization

Quick changeover

LANGGUTH has developed three moduLAN modules with distinct number of container plates to achieve both speed and required labelling functions. Plate rotation necessary for the labelling process is performed in continuous mode by a central drive or by individual servo drives tied to each plate. Cameras or special sensors within the labelers ensure non-contact container orientation. Furthermore supplementary coding and control devices can be integrated easily.

Technical data: moduLAN 818 moduLAN 816 moduLAN 824

Number of labelling aggregates: 2 3 5

Pitch: 120 mm 180 mm 180 mm

Container diameter: 100 mm 160 mm 200 mm

Basic frame: Welded, stainless steel square tube

Container rotation: Continuous mode or servo motor for each plate

Glue pallet – wet glue with traditional glue pallet label transfer

When direct label transfer with the FVT18 is not possible, the moduLAN is equipped with traditional glue pallets reliably used by the beverage industry for the application for the front, back, patch, shoulder or neck ring labels.

Technical data: (basic)

Speed: Up to 24.000/hour depending on container specs

Labelling: Front, back, shoulder, neck ring

Label length: Up to 180 mm possible

Labels: Rectangular or shaped labels

FVT 18 – wet glue technology

In contrast to the glue pallet technology the LANGGUTH wet glue magazine FVT 18 permits the processing of labels which are longer than 200 mm. Furthermore the FVT 18 offers a significant cost savings and simplicity by eliminating the need for change parts for different size labels.

Technical data: (basic)

Speed: Up to 15.000/hour depending on container specs

Labelling: Mainly wraparound or partly wraparound for cylindrical jars

Label length: Min. 80 mm – max. 400 mm

Label height: Up to 210 mm

Labels: Rectangular or shaped labels

Hotmelt Technology

The glue-saving spray hotmelt system permits speeds up to 60.000 containers per hour and applies wraparound labels onto all kinds of cylindrical containers.

Technical data: (basic)

Speed: Up to 60.000/hour depending on container specs

Labelling: Mainly wraparound onto cylindrical and angular containers

Label length: More than 500 mm possible

Label height: Max. 235 mm

Labels: Rectangular labels made of paper or plastic

Self-adhesive labellers

In addition to product labels, also applies special labels for promotional activities, coloured stickers or ID labels can be applied by self-adhesive dispensers.

Technical data: (basic)

Labelling: Front-, back-, seal Labels and coloured stickers, special labels for promotional activities or ID labels

Label height: Max. 320 mm

Labels: Rectangular or shaped labels made of paper or plastic

Operation:

The labeller works on a rotary principle and can be equipped with different labelling modules. The infeed worm controls the container infeed and creates a defined gap between the containers which matches the pitch of the infeed star. The infeed star guides containers onto the centering plates of the carousel. Then the centering heads fix the containers on the centering plates.

Wet glue module FVT18

In the glueing device of the wet glue module FVT18 the glue is pumped and recirculated over the rotating glue roller and returned via a hose. An even glue film covers the glue roller. The labels are positioned vertically in the stationary label magagine. A vacuum bar picks up the label from the magazine and transfers the label to transports belts. After moving through the belt transport section the label meets the glue roller which applies an even thin film to the entire backside of the label. The label edge is deflected off the glue roller onto the container. The entire label wraps around the container and is wiped tightly to the container.

39 autres produits dans la même catégorie :

- Neuf

- Neuf

- Neuf

Machine for the production of thermoshrinking bags SA-V TVB

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT