- Neuf

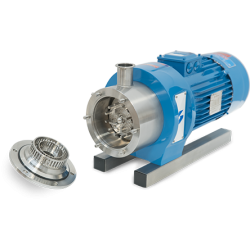

DLM/H Inline Homogenizer

High shear mixing for emulsifying and dispersing.

Description

The INDAG Inline Homogenizer type DLM/H is used for effective emulsifying, dispersing and mixing liquids and solids. A typical application for the INDAG Inline Homogenizer is the disintegration (de-agglomeration) of lumps in pumpable media. For example, in the production of cosmetics, oil, water and emulsifier are combined to form a stable emulsion. Mayonnaise is produced from oil, vinegar solution and egg by a homogenizer type DLM/H. Droplet sizes of less than 1 µm are achieved at rotor peripheral speeds > 20 m/s and very narrow gap dimensions. Another example of the use of the INDAG Inline Homogenizer is the mixing of phosphoric acid or citric acid into vegetable oil for degumming.

Advantages of DLM/H

- Very good self-cleaning during CIP-cleaning

- Efficient introduction of mixing energy

- Modular design of homogenizer

- Hygienic design

- Execution with double jacket and further connections possible

- Various special designs available, e.g. for high pressure or high viscosity.

Technology of DLM/H

The INDAG homogenizer type DLM/H has a rotor and a stator. These are provided with axially arranged mixing/shearing elements. Rotor can be designed to be cooled or heated. The homogenizers are of modular design, four diameters with 2 or 3 mixing stages are available. The DLM/H is offered in compact design (KB) and in bearing block design (LB). In the compact design, the rotor is mounted by the output shaft of the motor. In the bearing block design, the rotor is mounted by its own bearing block. With own bearing block, narrower shear gaps and thus a more intensive shear effect can be realized. Furthermore, this design is also suitable for mixing under high pressure or high temperature. The type of rotor seal is selected to suit each application. For the supply of the double-acting mechanical seal INDAG offers the suitable locking system.

Positioning

Horizontal or vertical position of mixer is possible

Pressure levels

6 bar, 10 bar, 16 bar, 25 bar, 40 bar

Materials

1.4404 (AISI 316 L) or higher quality on request

Seals

Single acting mechanical seal; double acting mechanical seal; even in aseptic execution

Connections

Dairy connections according to DIN 11851, DIN 11864, Tri Clamp, SMS and various others on request

Rotational speed

1,500 rpm to 6,000 rpm

Capacities

50 l/h to 120,000 l/h

Temperatures

0 °C to 250 °C

Viskosities

1 mPas to 500,000 mPas

2 autres produits dans la même catégorie :

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT