- Neuf

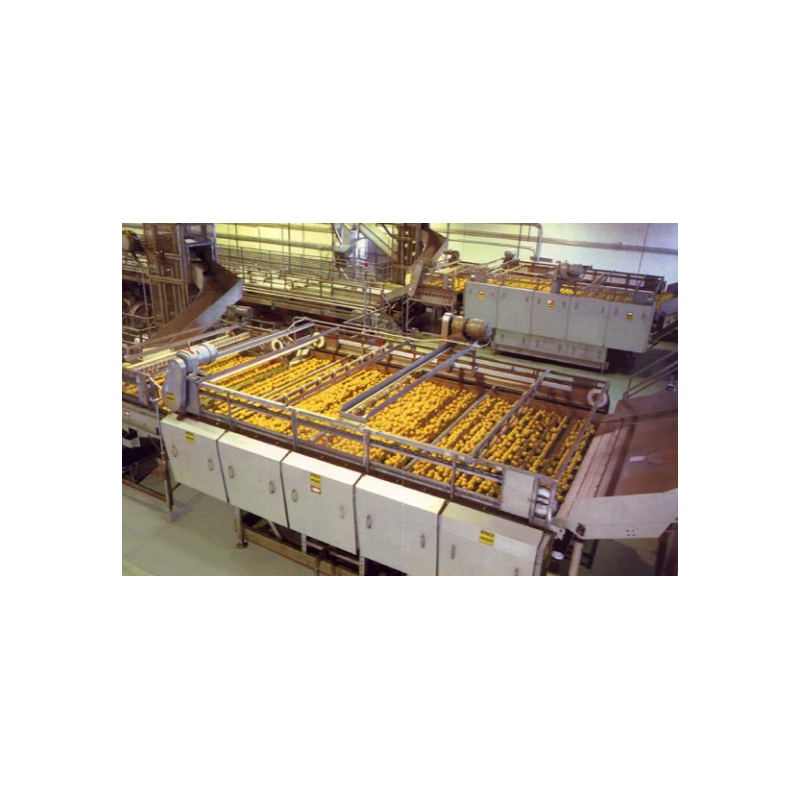

Brown Oil Extractor Model 6100

The design and technology incorporated in the BOE assures the customer the highest possible quality and yields of cold pressed citrus oil.

Description

APPLICATIONS: The Brown Oil Extractor (BOE) is the key element in the Brown Oil recovery System. The design and technology incorporated in the BOE assures the customer the highest possible quality and yields of cold pressed citrus oil.

There are in excess of 70 BOE systems in service worldwide. Ongoing Research and Development insures the Brown Oil Recovery System will remain the preferred choice for customers demanding the utmost performance.

BOE OPERATION: Whole citrus fruit is delivered to the BOE by a metering elevator, which assures a steady and consistently controlled operation. A patented interrupter gate is incorporated into the inlet chute feeding the BOE. This brief pause in fruit flow allows additional time for the fruit to settles in the BOE for maximum performance.

The Brown Oil Extractor liberates the essential oil from whole citrus fruit. The oil removal is achieved by lightly puncturing the entire surface of the fruit with over three million sharp stainless steel points configured in the form of rotating rolls. An adjustable speed differential between adjacent rolls controls the amount of work applied to the fruit.

For complete coverage of an elongated fruit such as a lemon, the rolls not only rotate, but also oscillate horizontally in opposite directions causing the entire peel surface to be punctured, releasing the oil. The puncturing operation takes place beneath the surface of a shallow pool of water contained in the BOE to insure that there is no loss of oil to the atmosphere.

A dryer composed of specialized rollers removes any water and oil clinging to the fruit surface after its discharge from the BOE. This liquid is added to the oil/water stream leaving the BOE.

A significant advantage to the BOE method of oil removal is the extremely free oil/water stream produced by this unique puncturing method. The BOE ruptures oil cells and liberates the essential oil with minimum disruption to the whole fruit and negligible extraction of pectin from the peel. This produces oil that separates effortlessly from the water phase.

After leaving the BOE, the oil/water mixture passes through a fine screening operation in preparation for centrifugation. A first centrifuge produces a stream of rich oil. The water phase from this centrifuge is recycled back to the BOE to eliminate losses. Without costly freezing or enzyme treatment, the rich oil stream passes through a second centrifuge which continuously produces pure polished oil.

SPECIFICATIONS: Model BOE

Overall length 15’ 3-7/8” Capacity - input Fruit tonnage & yields

Overall width 11’ 1-1/2” vary based on configuration

Overall height 8’ 9” Horse power std. drive 24 HP Total

63 autres produits dans la même catégorie :

- Neuf

- Neuf

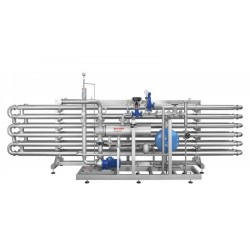

PEF Advantage B 1, B 1 mini, 10, 100 & 1000

- Neuf

- Neuf

- Neuf

Machine for pitting cherries 250-300 kg/hour Harver DM300x2

- Neuf

PTCX Turbo Depitter for Peaches and Apricots Continuous process

- Neuf

- Neuf

PEF ADVANTAGE B 1 PULSED ELECTRIC FIELD SYSTEM

- Neuf

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT