- Nuovo

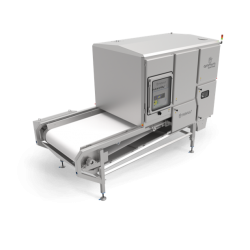

CLEARFLOW P MEMBRANE FILTRATION SYSTEMS

FILTRATION PLANTS FOR STERILE SENSITIVE PROCESSES IN BIOTECHNOLOGY AND FOOD INDUSTRY

Descrizione

CLEARFLOW P Filtration Systems in “Hygienic Design” are cross-flow filtration systems (also named tangential flow filtration) for the biotechnology and food industries where increased hygiene requirements must be met.

Depending on the application, the filtration plants are specially designed for the medium and the possible contamination risks. In particular, rheological and dynamic characteristics of the substance to be filtered are taken into account when determining the filtration modules

SUSTAINABLE AND SAFE FILTRATION WITH CLEARFLOW

In the control system extended program structures, safety devices and special sequences and controls to ensure sustainable and safe filtration are implemented.

All filter plants are equipped with periodic backflushing. Depending on the sensitivity of the product, the backflushing is performed with sterile compressed air or with hygienic pumps and the filtered medium.

CLEARFLOW P systems essentially consist of the following system components:

- Polymer or ceramic filtration modules

- Hollow fiber modules, tubular modules, filter cassettes or wound modules

- Pressure pump and circulation pump with frequency converter

- Circulation tank unit

- Compressed air system

- Filtrate pump with filtrate tank (optional)

- Stainless steel grade of all materials: 1.4404

- Surfaces in contact with product with Ra ≤ 0.8 µm, optionally with electropolishing

- Piping and fittings (e.g. in DIN 11864 and DIN 32676)

- CIP and SIP unit for cleaning and sterilization (optional)

- Compact frame to hold all pipes and aggregates

- Prefilter units (optional)

- Condensate system for SIP capable systems

- Pressure control/regulation

- Temperature control/regulation (optional)

- Advanced sensor technology such as turbidity, conductivity, pH etc. (optional)

- Central control unit with SIEMENS SPS and touch panel

DESIGN

FRINGS CLEARFLOW filtration systems can be equipped with membrane modules with different flow characteristics, materials and cut-offs.

Depending on the cut-off and transmembrane pressure, CLEARFLOW filtration systems can be classified as microfiltration (MF), ultrafiltration (UF) or nanofiltration (NF).

The process and equipment design is carried out in close cooperation with the customer. The basic process engineering tasks, material selection and the required separation efficiency are specified exactly and the design of the plants is also supported by pilot tests.

Depending on the application, short cut tests or special test series with the original media are carried out.

Different Design Standards of FRINGS Membrane Plants:

- CLEARFLOW P: Membrane plants for sterile technical processes in food and biotechnology

- CLEARFLOW B: Membrane systems for hygienic processes, especially in breweries, baker’s yeast and beverages

- CLEARFLOW G: Systems with equipment and documentation according to GMP pharmaceutical standards

- CLEARFLOW C: Membrane systems without sterile or hygienic design according to chemical standards (e.g. for auto sterile media)

- Made from: Stainless steel

73 altri prodotti della stessa categoria:

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

- Nuovo

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT